In recent years, laser surface treatment has gained popularity due to its efficiency and effectiveness. Today, laser applications in manufacturing are numerous. Building on these established techniques, new thermal laser processes are emerging that activate surfaces before the application of glues or adhesive films. This growing interest stems from laser process development, improved system integration and higher throughput.

Laser Processing Effects on Surface Properties

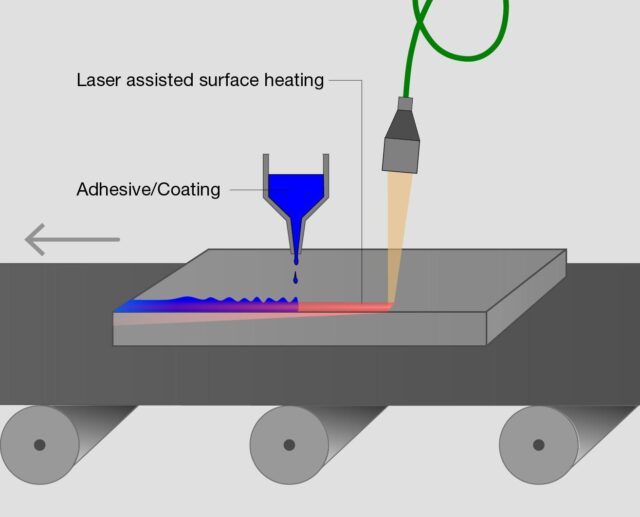

Lasers are widely used for marking, welding, sintering, bonding, cutting and soldering. Now their application in thermal surface activation is becoming more popular. This innovative process utilises lasers to prepare surfaces before adhesive application, by modifying the surface properties to facilitate bonding.

Depending on the composition of the substrate, heating from laser surface treatment modifies it in several ways:

- Surface Roughness Modification: Laser heat treatment can modify the roughness of a surface depending on the laser type. Continuous lasers can reduce surface texture, which is often favourable for the adhesion of films. This is mediated by laser heating. Pulsed lasers can increase surface roughness through a process known as micro-ablation, which can improve surface adhesion for glues.

- Laser Heat Treatment Effects: Heating with a laser is fast and intense, resulting in a rapid rise in surface temperature. High temperatures lower the viscosity of subsequently applied glues and increase wetting properties.

- Laser Surface Cleaning Efficacy: Laser treatment of a surface eliminates tiny dust particles from the surface, as well as oily residues or oxide films, which interfere with the adhesion of glues or films.

Laser Processing Technology

Successful applications depend on understanding substrate properties, laser characteristics and the specific application requirements. Laser process development is a crucial step in ensuring optimal adhesion outcomes.

Hamamatsu Photonics offers a wide selection of fibre-coupled near-infrared (NIR) lasers1 that can be customised for wavelength, power, and beam shapes. These laser systems can be optionally equipped with built-in temperature monitoring, significantly shortening the development period for our customers’ laser applications.

Incorporating this technology into industrial laser processing is leading to innovative methods for enhancing adhesion. By leveraging techniques such as laser surface cleaning, laser heat treatment, and tailored process development, manufacturers can achieve superior bonding results, enabling more efficient production lines and improved product performance.

For more information on laser processing and laser surface treatment, please visit www.hamamatsu.com or contact info@hamamatsu.eu.

References

- Hamamatsu Photonics “Applied products of semiconductor lasers” available: https://www.hamamatsu.com/eu/en/product/lasers/applied-products-of-semiconductor-lasers.html