tesa, an international manufacturer of innovative adhesive tapes and self-adhesive product solutions, is implementing a large-scale power-to-heat plant with integrated thermal storage at its Hamburg plant – the largest production site in the global tesa network – in collaboration with ENERGYNEST, an international provider of power-to-heat and thermal energy storage solutions for industrial process heat. The facility will supply a substantial share of the site’s energy-intensive process steam generation in a climate-neutral way going forward.

The system will reduce CO₂ emissions at the Hamburg site by around 4,600 metric tons per year—approximately 20 percent of site-related emissions based on the 2018 reference year. The energy concept can be flexibly transferred to other energy-intensive production sites, particularly in the chemical industry as well as in paper and food manufacturing. tesa and ENERGYNEST are already assessing the rollout of the concept to additional plants.

Energy-intensive production meets intelligent electrification

The tesa plant in Hamburg manufactures high-performance adhesive tapes for the electronics, automotive, printing, and paper industries. Drying processes and solvent recovery require large amounts of process heat and steam, which until now have been generated primarily from fossil fuels.

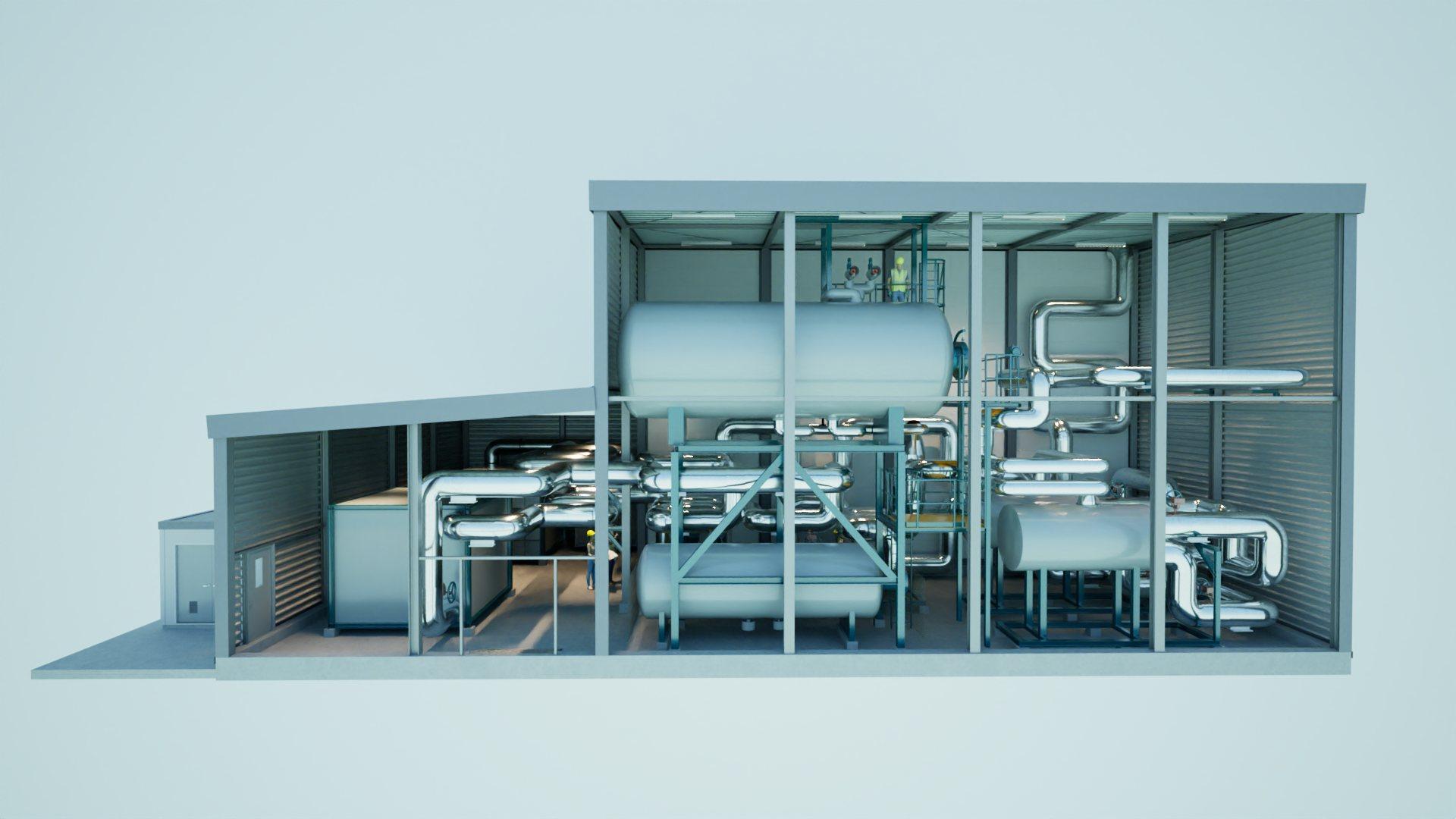

A key element of the transformation is the electrification of steam generation: a 10 MW power-to-heat system with a 40 MWh thermal energy storage unit from ENERGYNEST enables electricity from renewable sources to be converted into high-temperature steam and made available at different times. This allows around two-thirds of the site’s annual steam demand to be covered in a climate-neutral, flexible, and grid-supportive manner.

The thermal storage facility consists of 24 modules in which heat is stored in concrete pipes and transported via thermal oil – comparable to heated concrete, which continues to reliably release heat even hours after charging. The system is designed for an operating life of at least 25 years and is characterised by particularly low-maintenance operation.

Grid-friendly, economical, and scalable

The thermal storage system allows the targeted use of inexpensive surplus electricity from renewable energies and flexible adjustment of electricity procurement to market prices, weather, and grid load. An AI-supported control system links power-to-heat, PV, wind, and other efficiency measures into an intelligent overall system.

“This project shows that climate-neutral industrial production is already feasible today – technologically, economically, and scalably,” says Dr Ingrid Sebald, Chief Technology Officer, tesa SE. “With the electrification of our steam generation and the integration of a large-scale thermal storage system, we are adding another key building block to our transformation and creating the foundation for near climate-neutral production in Hamburg.”

“Together with tesa, we are implementing one of the largest commercial power-to-heat plants with thermal storage for industrial processes in Germany. The project sets new standards for industrial electrification and shows how thermal storage and flexibility is becoming an enabler of the energy transition,” adds Alex Robertson, CEO, ENERGYNEST.

Part of a global sustainability strategy

The power-to-heat plant with thermal storage in Hamburg is a key milestone in the group-wide sustainability strategy “we do” and on the path to climate-neutral production by 2030. To implement this, tesa is investing around 300 million euros worldwide in the sustainable transformation of its business. With a 39 percent reduction in CO₂ emissions (Scope 1 and 2) already achieved, the company is well on its way to reaching its goal. Today, tesa already covers 90 percent of its global electricity needs from renewable sources. The holistic transformation concept for the Hamburg plant is based on four pillars and has been honored with the dena Energy Efficiency Award.

Groundbreaking for the power-to-heat system and thermal energy storage facility is scheduled for fall 2026. Commissioning is expected to take place in summer 2027.