Together with 24 German research institutions and companies under the coordination of Forschungszentrum (FZ) Jülich, Fraunhofer IPMS is working on an integrated German quantum computer based on superconducting quantum chips and with improved error rates. Halfway through the project, the first demonstrator can now be put into operation. The CNT at Fraunhofer IPMS is contributing its expertise in state-of-the-art, industry-compatible CMOS semiconductor manufacturing.

Quantum computers are seen as the central solution for the increasing demand for more and more computing power and larger amounts of data. However, in order to make quantum processors applicable and scalable, there are still various hurdles that need to be overcome. The error-proneness of quantum bits, or qubits for short, is currently considered one of the biggest challenges in quantum computer development. The aim of the partners is to develop a system with various quantum processors based on next-generation superconducting circuits and that has a very low error rate. This means that the qubits achieve a higher quality. The approach is world-leading and is likewise being pursued by Google, IBM and Intel.

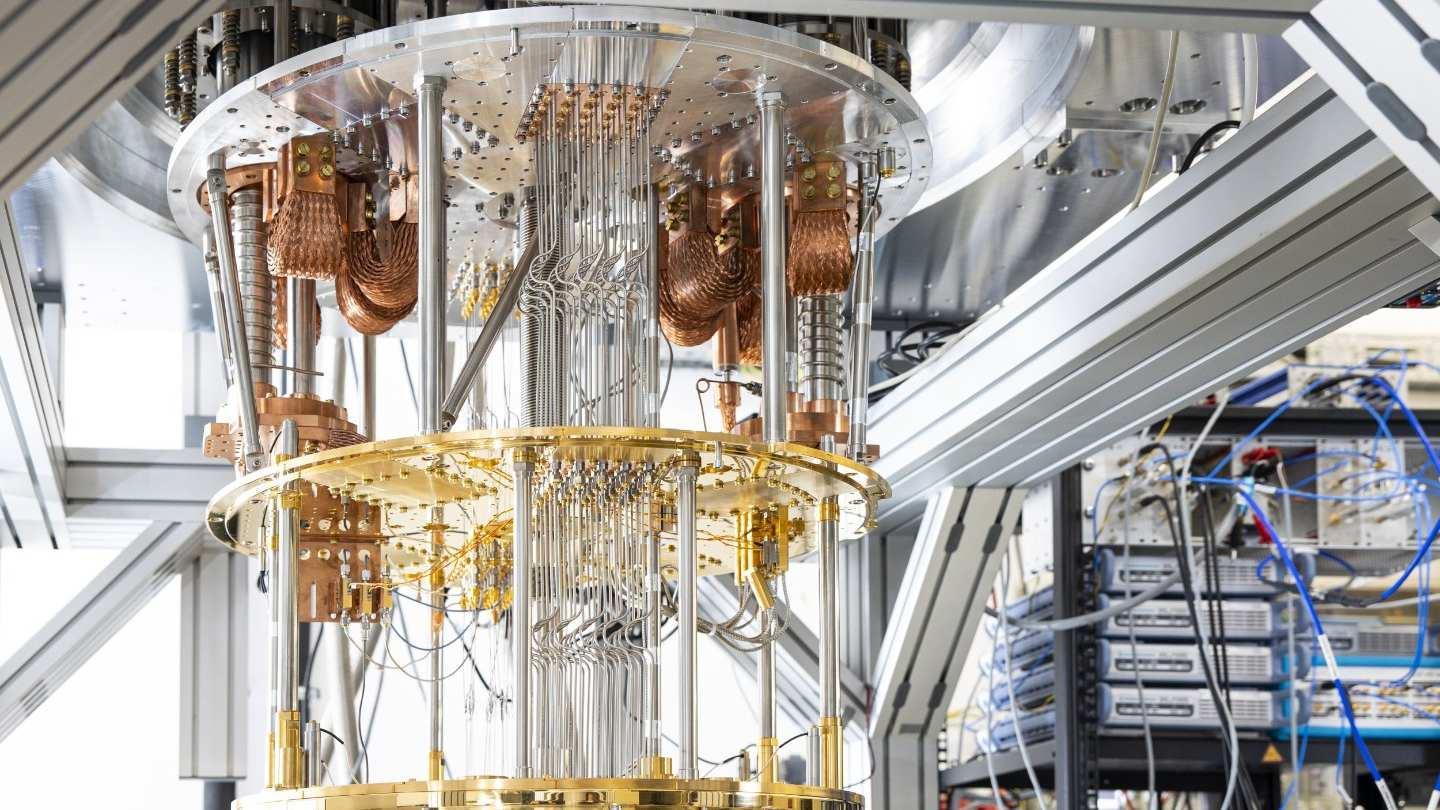

As an overall milestone, a first prototype of the QSolid half-time demonstrator with 10 qubits, an integrated software stack and cloud user access will soon go into operation at Forschungszentrum (research centre) Jülich, making it possible to test applications and benchmarks for industry standards. The project is supported by the German Federal Ministry of Education and Research (BMBF) with a total of € 76.3 million.

Achievements from semiconductor manufacturing used for quantum processors

Fraunhofer IPMS is part of the work package “Technology for Hardware Integration”. Together with GlobalFoundries and Fraunhofer IZM-ASSID, it is working on the co-integration of a CMOS control logic together with the quantum processing unit (QPU) in order to reduce complex cabling and lines in the quantum computer. These complex structures could reduce the conductivity of the processor and thus make it more difficult to keep the temperature of the whole system low – especially if the number of qubits increases in future processors. To this end, an interposer technology is being developed that focuses on high-density, superconducting connections and thermal decoupling through advanced packaging. The challenge is to keep the CMOS chips usable under cryogenic conditions as the temperature of the processors needs to remain low for the qubits.

The Center Nanelectronic Technologies (CNT) utilises its expertise and infrastructure in state-of-the-art, industry-compatible CMOS semiconductor production in the 300 mm wafer standard. This concerns, for example, manufacturing processes such as deposition and nanostructuring at wafer scale or cryo-electric characterisation. “Together with our partners in Dresden, we were able to define the design for the joint CMOS and quantum chip integration as well as suitable materials regarding the temperature management. Based on this, a first generation interposer was manufactured and successfully tested under cryogenic conditions. This also included the demonstration of superconducting properties of the materials used, such as the indium-based bumps. In addition, the tests for the cryogenic characterisation of the CMOS chips by GlobalFoundries were successful,” announces Marcus Wislicenus, head of Quantum Technologies at Fraunhofer IPMS.

A shared quantum computing infrastructure at FZ Jülich

The 10-qubit prototype is only an intermediate step towards higher scaling. By the end of the project in December 2026, the system is to be further developed so that it can control 30 qubits at best and with the greatest possible error correction. “Over the last two and a half years, we have built up excellent capacities and launched a system with promising performance values. While we are still integrating and controlling the final subsystems, we are already working on increasing the performance of the prototype, which is intended to handle complex computing operations for applications in industry and science,” says project coordinator Professor Frank Wilhelm-Mauch.

In order to achieve the ambitious goal of an independent quantum computer manufactured in Germany, QSolid brings together 25 research institutions companies and start-ups from all over Germany. Together, the project partners want to pave the way for commercialisation and develop a demonstrator that will be available to external users via the “Jülich UNified Infrastructure for Quantum computing” (JUNIQ) and tailored to their individual needs.