In a world where sustainability and economic efficiency are becoming increasingly important, INOMETA is setting new standards with its heating rollers, winding cores and its innovative INOid and INOlink products. This article highlights how the company, based in Herford, Germany, is creating both ecological and economic advantages through innovative technologies and intelligent product solutions.

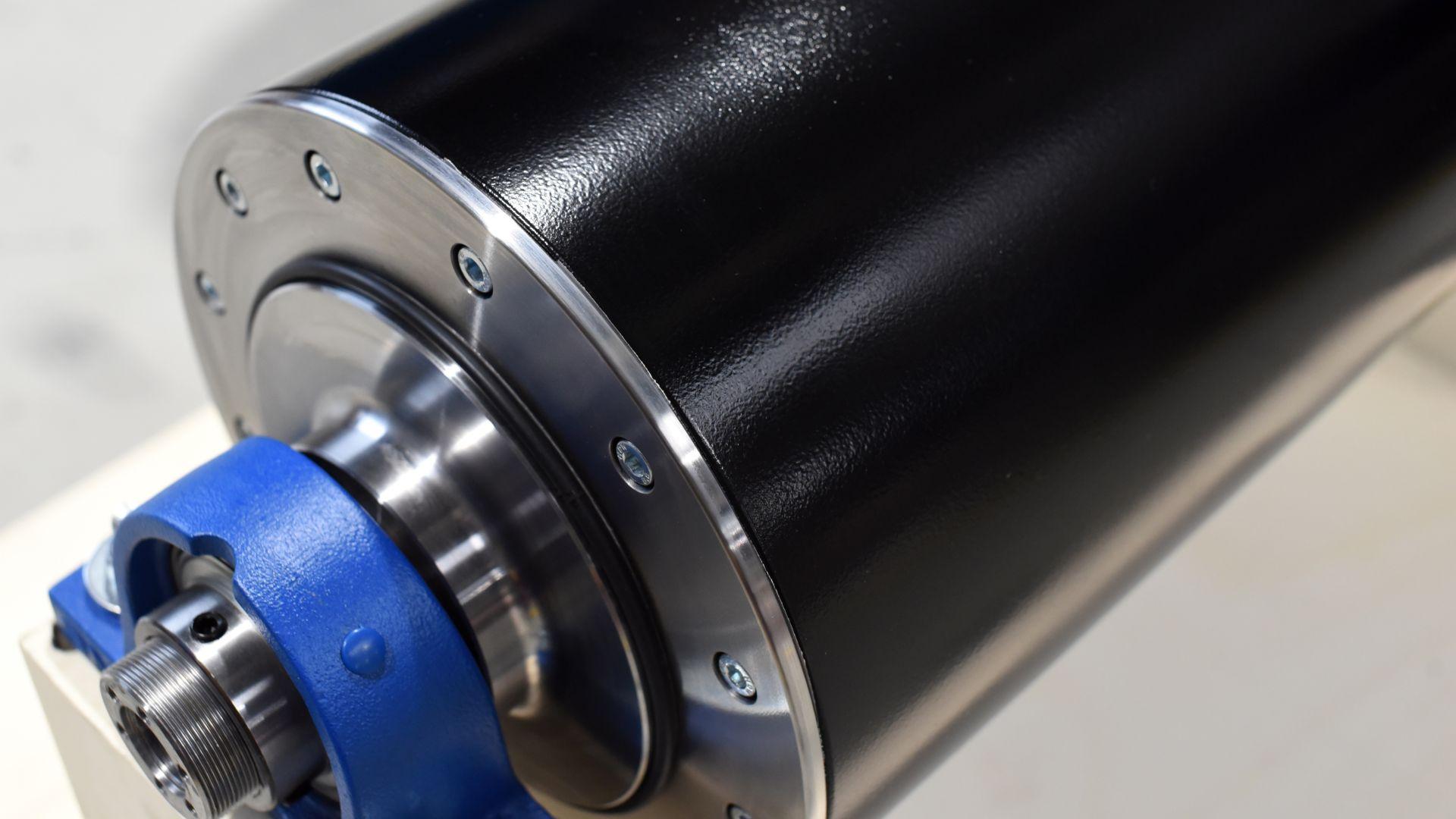

INOMETA’s electric heating roller is a prime example of technological innovation that increases energy efficiency in production. Unlike conventional heating rollers, which are based on liquid media such as oil or water, the INOMETA heating roller generates the required heat locally, using electrical energy directly within the roller. This minimises energy loss and ensures that the supplied energy almost completely corresponds to the required useful energy. This leads to a significant reduction in the overall energy requirement and thus to lower operating costs and a reduction in CO2 emissions.

Another advantage of INOMETA’s heated roller is that it eliminates the risk of leaks that could contaminate the environment or the substrate. Furthermore, the elimination of oil-based heating media enables a more environmentally friendly recycling process. The heated roller is easy to install and saves space, as no storage tanks, pipes or pumps are required. The recognition of INOMETA’s heated roller as a sustainable and economical solution was confirmed by the ICE Europe Award 2023.

Alternatives to conventional cardboard cores

INOMETA’s WinCore series offers a sustainable alternative to conventional cardboard cores. Thanks to their durability and reusability, they help to reduce waste and conserve resources. A single aluminium winding core can replace up to 500 cardboard cores and can be reused up to 1,000 times. This long lifespan contributes to sustainability and cost-effectiveness and significantly reduces the ecological footprint of production processes.

The use of WinCore winding cores is a clear commitment to sustainable production methods and shows how productivity and environmental awareness can go hand in hand.

Air supply system for flexographic printing

INOlink, INOMETA’s air supply system for flexographic printing, is another innovation that reduces compressed air consumption in the printing unit by up to 80%. This reduction leads to significant savings in operating costs and thus to a higher profitability of the printing process. Furthermore, it also results in a reduction of CO2 emissions and an optimisation of occupational safety by reducing noise emissions by up to 10 dB during the set-up process. The prevention of air turbulence in the printing unit also helps to prevent contamination and sustainably improves print quality. INOlink is backwards compatible with the existing INOflex product portfolio, enabling a step-by-step transition.

Digital platform for product data

INOMETA is not only committed to innovative developments in the field of hardware but is also getting involved in digital solutions for the first time with INOid. With this innovation, INOMETA provides a digital platform that enables efficient management and quick access to product data. The system helps companies optimise their processes and minimise downtime and errors. This results in significant cost savings.

INOid also contributes to sustainability by reducing paper consumption and the need for physical documentation. By using QR codes and RFID tags, INOid enables fast and reliable access to product data, which in turn increases efficiency. The intuitive user interface and easy integration into existing systems are another highlight of INOid. This strategic expansion of the product portfolio underlines the company’s commitment to being a leader in the technology industry and continuously breaking new ground to meet the demands of an ever-changing market.

Conclusion

With its products – heating rollers, winding cores, INOlink and INOid – INOMETA shows how sustainability and profitability can go hand in hand. By using energy-efficient technologies, reusable materials and intelligent networking solutions, INOMETA is making a significant contribution to reducing the consumption of resources and costs. The future of production lies in achieving a balance between economic success and ecological responsibility. With its products, INOMETA demonstrates that this balance is achievable and sets new standards for a sustainable industry. By using INOMETA’s innovative solutions, companies can not only reduce their costs, but also strengthen their market position and contribute to the protection of our planet.

INOMETA

Caption: An electric heating roller from INOMETA