Under the slogan ‘Empowering Vision Excellence for Print Inspection’, ISRA VISION, a global leader in machine vision, will be presenting numerous new developments from its comprehensive range of inline inspection solutions for the printing and packaging industry at drupa 2024 (hall 10, booth A28). The range of products covers the entire production process, from machine set-up and the printing process itself through to converting. Innovative software and analysis tools complete the portfolio. ISRA VISION’s solutions can help to further boost process efficiency and product quality, increase yields, and reduce production costs and environmental footprint.

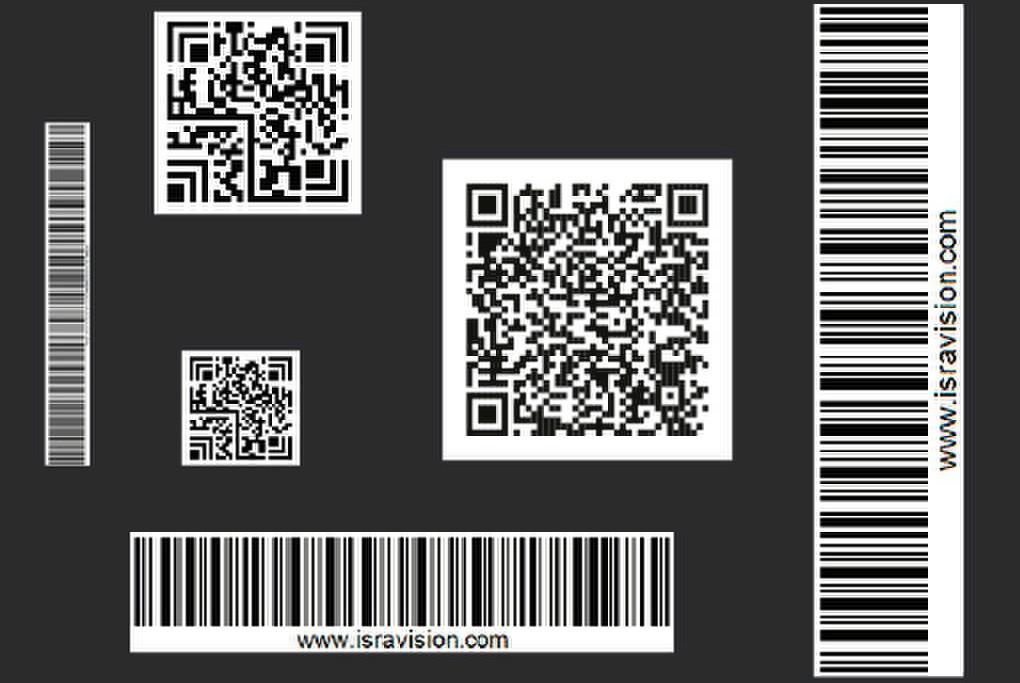

At drupa, ISRA VISION is presenting a new version of PrintSTAR EVO, its tried and trusted system for inspecting web material for flexible packaging. The new ‘Static Code Reading’ function now makes it possible to check the legibility of barcodes and QR codes. The system reads the code and informs the operator whether it is legible, allowing any appropriate action to be taken in good time.

Enhanced camera technology

PrintSTAR EVO’s enhanced camera technology ensures even better detection of typical printing errors such as splashes and spots, missing ink, register errors, streaks and drags as well as dirt. The system also still includes its ‘MultiView’ functions in which multiple camera banks simultaneously carry out further inspection tasks. This also enables the detection of initially invisible production defects such as hazing as well as decorative varnish defects or cold sealing defects.

Another new feature is the modern ‘Touch&Inspect’ graphical user interface, which is now also available not only for PrintSTAR EVO but also for CartonSTAR, ISRA VISION’s inspection solution for corrugated board printing. Featuring intuitive and device and location-independent operation via a web browser, its custom-configurable dashboards provide users at a glance with exactly the information they need to carry out their jobs. The new GUI also enables further improved visualisation of colour monitoring.

Shorter set-up times thanks to ‘RegisterControl’

‘RegisterControl’, which automates setting up flexographic printing units in register, is a new function for ViewSTAR, ISRA VISION’s web monitoring system. The system uses print marks to check the position of each colour printing unit. The values are then forwarded to the printing press, which adjusts the process for optimum register accuracy. Advantages include greater ease of use, shorter set-up times, and less paper wastage.

All-in-one solution for unprinted and printed web material

Another highlight at ISRA VISION’s booth is DualSTAR, which combines the functions of the SMASH and PrintSTAR products in a single system. DualSTAR is capable of inspecting not only unprinted web materials, such as films but also printed materials. This is of particular interest to users in the converting sector, as they need just one inspection system on the appropriate machines such as laminators, rewinders or slitters. And thanks to 100% inline inspection, DualSTAR helps not only to further boost quality but also to reduce costs.

EPROMI uncovers hidden potential

EPROMI is ISRA VISION’s powerful optional production management intelligence tool and the company’s print inspection solutions are now equipped with the necessary interface so that customers from the printing and packaging industry can also benefit from it. Not only does it enable real-time monitoring of processes and inspection systems, but in-depth analysis of the recorded production and inspection data enables EPROMI to uncover hidden potential and assists with informed decision-making to further enhance process efficiency and quality and boost yields.

Visitors to ISRA VISION’s booth at drupa will also be able to find out more about new developments for inspecting printed metal sheets as well as novel solutions for digital print inspection.

https://go.isravision.com/isra-vision-at-drupa-2024

Caption: New functions for print image inspection from ISRA VISION: Thanks to the new ‘Static Code Reading’ function, it is now also possible to check barcodes and QR codes for readability. The system reads the code and informs the operator whether it is readable