As end-customers demand faster delivery and higher-quality products, converters and manufacturers of thin web materials – such as plastics, films, paper, labels and metallic membranes must find ways to optimise their web line operations. However, with numerous factors affecting web line performance, including tension variations, material changes, and control strategies, identifying the right approach can be overwhelming.

Join Maplesoft’s webinar to learn how simulation can help optimise roll-to-roll (R2R) systems, improve the handling of web material, and prevent common production issues before they arise.

Simulation to the rescue

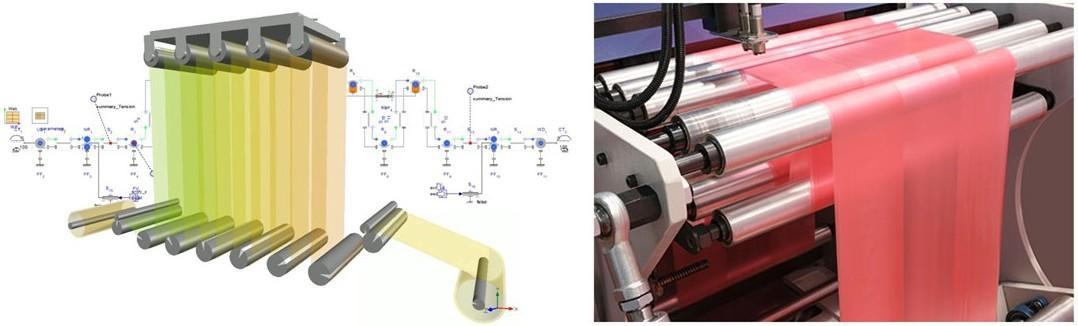

Simulation offers a powerful way to tackle these challenges. By using modelling tools, manufacturers can determine roller setpoints, identify tension hotspots, and prevent issues before they occur. Yet, for those who have not yet implemented simulation, it can be unclear how to get started or maximize its benefits. This webinar will provide valuable insights into the value of using simulation when configuring web handling and converting processes.

What does Maplesoft offer?

Maplesoft is a leading provider of advanced modelling and calculation solutions for engineers and researchers, serving over 8,000 organisations in more than 90 countries. MapleSim software helps R2R engineers maintain product quality by modelling the responses of web materials through rollers or converting processes and by determining optimal tension setpoints.

With a specialised library of converting components, MapleSim simplifies the modelling of dancers, nips, idlers, and driven rollers, making it significantly faster than traditional 3-D CAE mesh models. In addition to software, Maplesoft provides expert consulting and modelling support to help engineers maximize the benefits of virtual roll-to-roll modelling.

What attendees can learn

In this webinar, Maplesoft’s Senior Director, Solutions, Chad Schmitke will demonstrate how engineers can use simulation tools to enhance roll-to-roll systems, refine tension control strategies, and adapt to new materials. Attendees will also learn how to use visualization techniques to uncover operational issues such as slippage before they impact production.

Key topics covered:

• The value of a simulation-based approach for improving web line design

• How to apply digital modelling to web handling or converting operations, with practical steps to get started

• Diagnosing and avoiding tension problems through accurate system modelling

• Using simulation to evaluate the impact of new web materials and test tension control strategies

• Real-world examples of companies that have improved machine performance and reduced troubleshooting time through simulation

Join the conversation

Don’t miss this opportunity to explore how simulation can transform web handling and converting systems!

Register Here