New Era Converting, recently acquired by IPCO, will exhibit in a combined booth with its new owner for the first time at The Battery Show Europe from 3-5 June at Messe Stuttgart.

New Era will spotlight its expertise in calendering systems and roll-to-roll coating equipment, together with IPCO’s full range of solutions for the development and production of next-generation separators, barriers, membranes and multi-layer electrodes.

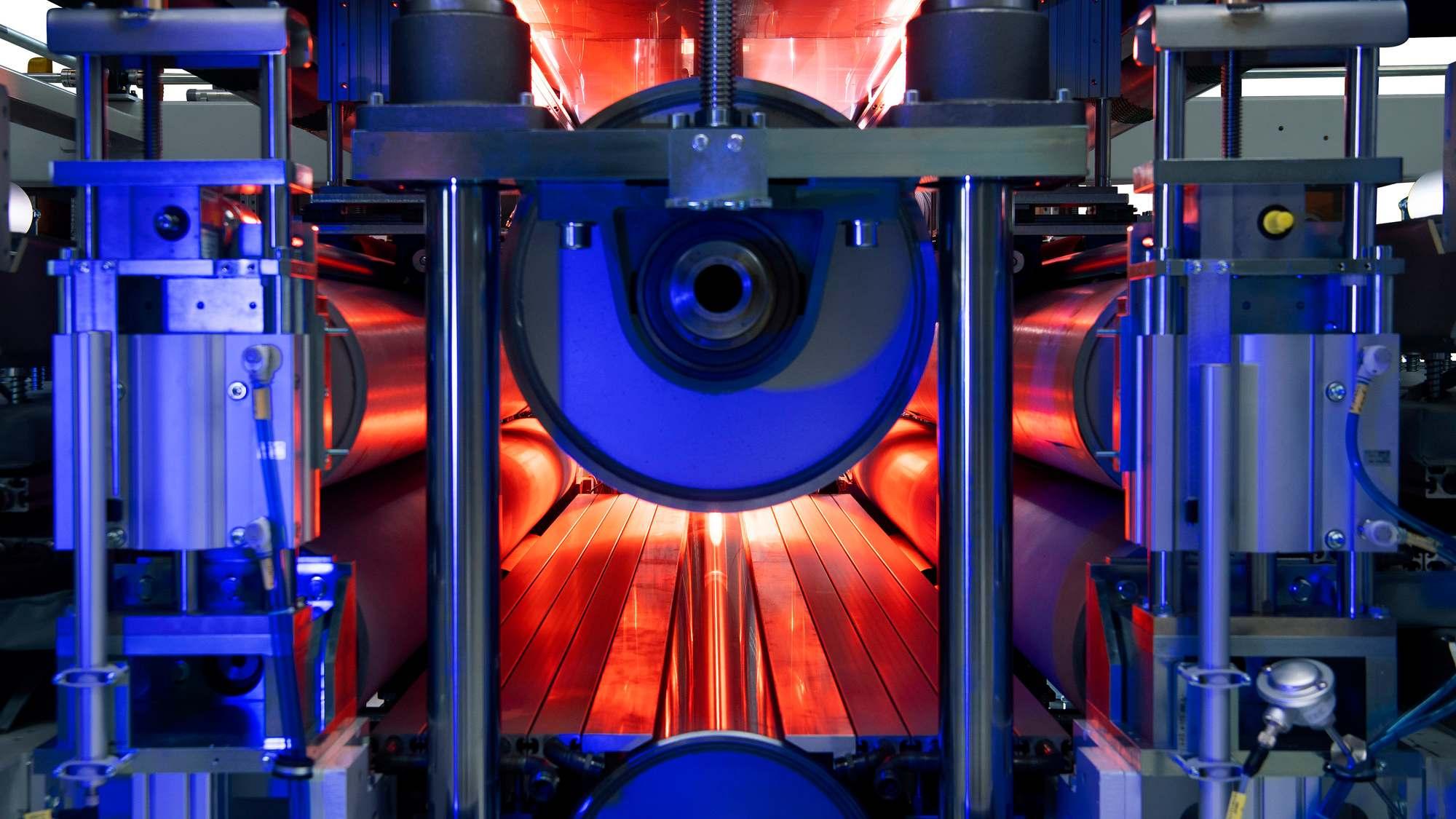

New Era calendaring, coating and web handling

New Era’s calendering equipment is custom-engineered to precise specifications to meet specific requirements, including process temperature, pressure, gap settings and width. Systems can incorporate features such as load cells for nip pressure readout and a number of different methods to counteract deflection, such as crowned rolls and roll bending. Other options include downstream thickness gauging for automatic, closed-loop gap control and recipes for line speeds, gap settings, tensions and pressures.

Additionally, New Era designs and manufactures pilot and production equipment for roll-to-roll anode and cathode coating, separator coating and specialty coatings for vibration dampening/thermal materials. The company has implemented simultaneous single-pass and dual-side coating for both horizontal and vertical drying applications, all driven by customer needs, substrates and coating rheology.

All the systems above require precise tension control and a range of different unwinding and winding technologies depending on the substrates. New Era provides these systems for both stop-and-go and continuous operation, utilising a variety of material cut-off techniques.

IPCO’s array of systems

IPCO is a leading manufacturer of advanced industrial process systems, with scalable production solutions for applications including thin film casting, scattering, calendaring and pressing/laminating. All systems are modular in design allowing cost-effective pilot-scale production for testing and evaluation, with the ability to scale up to industrial production. IPCO’s capabilities include:

- Thin film casting for separators, ceramic tape and membranes: IPCO’s continuous film casting system enables the production of film and tape products to exceptionally narrow tolerances. A slot die coater delivers a uniform casting of the product onto a continuously moving, polished steel belt. The film is carried to the IPCO Venturi dryer, a technology that eliminates any risk of skin formation on the product. The result is an end product of exceptionally high quality, with low stress and virtually no risk of fault and imperfections. Films can be produced in thicknesses from 10-300 µm, depending on the end application.

- Precision scattering for dry process electrodes: IPCO recently announced the launch of the ScatterPro BX, a system developed specifically to enable the precision scattering of powders used in dry process production of thin electrode layers. Innovative geometries and component design allow this unique system to distribute agglomerating powders – often clay-like in consistency with a tendency to clumping – in preparation for calendaring and laminating with the current collector material. The ScatterPro BX can be supplied in widths from 200 mm to 2000 mm, enabling solutions for everything from research facilities to full-scale production. Pilot plants are available for R&D and prototyping.

- ThermoPress double belt press systems: IPCO is a leading manufacturer of double belt presses for the continuous production of advanced composite materials. The ThermoPress range is unique in that solutions can be based on steel belts, PTFE belts, or a combination of the two. Delivering a carefully controlled pressure/temperature profile, these presses can be used for consolidating, compressing, laminating and densifying, making them ideal for processing continuous tapes or scattered powders for the production of multi-layer electrodes.

- Customer prototyping at advanced test facilities: IPCO will also highlight the availability of its productivity centres. These advanced R&D facilities are available for process assessment and product testing, with technicians and engineers available to provide full support. All IPCO systems – film casting, scattering, pressing and calendering lines – are available for product development and customer R&D.

Visit New Era and IPCO at Stand D76 in Hall 6.