Schobertechnologies GmbH specialises in the development, design and manufacturing of rotary tools, modules and specialty machines that are widely used in the film, foil, packaging, nonwovens and paper converting industries. This technically superior equipment is sold in more than 100 countries worldwide.

At the world’s leading plastics and rubber exhibition K2025, Schobertechnologies will present its industry-proven portfolio live from 8-15 October in Hall 3, Stand E72.

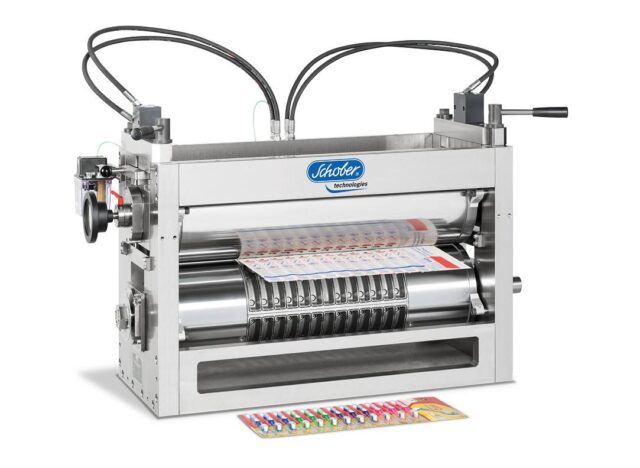

RSM520-DIGI-VARICUT with robot-automated stacking system

Special features of the automated high-speed delivery robot are the extreme acceleration combined with an excellent stacking precision at web speeds of up to 50m/min.

Exchangeable product specific pick-and-place gripper plates allow a maximum of flexibility and rapid change over time. The proven gripper plate technology ensures that products of different styles and forms can be handled – nonstop in dual piling cassettes. Even very long labels or heavily nested product arrangements can be stacked with highest precision. An inspection system for 100% quality verification with integrated waste separation is also available upon request.

Showcase of rotation cutting technology at the booth

Among other things, modules and tools will be exhibited at the booth, which can be used to specifically explain the rotary die cutting technology. Schober modules offer maximum safety and user-friendliness in pressure setting using proven load cells for pressure monitoring. Depending on the application area, cutting cylinders can be manufactured with cutting edges made of four proven materials: SuCR, Tungsten, Longlife and TC.

For small cut-outs, such as opening aids or ventilation holes, the use of high-performance punching modules is recommended. These can be individually configured with punching tools for dense hole patterns and have interchangeable punches and dies for punching paper, film and foils, some of which are thinner than 0.015mm.

Schober’s exhibition team will also be available to inform visitors about customised rotary cutting systems to produce blister packaging, insulation tapes for photovoltaic modules or roof ridge covers for the construction industry.

Schobertechnologies