SML’s latest cast film lines with an integrated MDO unit are designed to manufacture a wide range of MDO-PE films with different thicknesses and excellent barrier functionalities. These mono-material films are characterised by their high transparency and very good mechanical properties. Further processing on conventional machinery is straightforward and was tested satisfactorily.

“MDO-PE film was mainly developed to replace PET in PET-PE laminates to produce more environmentally-friendly, easy-to-recycle mono-material structures for a variety of flexible packaging products: from tubular bags for food packaging to side gusset bags, and from sealed bags to different types of pouches,” explains SML Product Manager Elias Mayerhofer. Barrier properties that are precisely tailored to the respective purpose play a key role in many of these applications.

17µm film with an EVOH barrier layer of less than 1µm

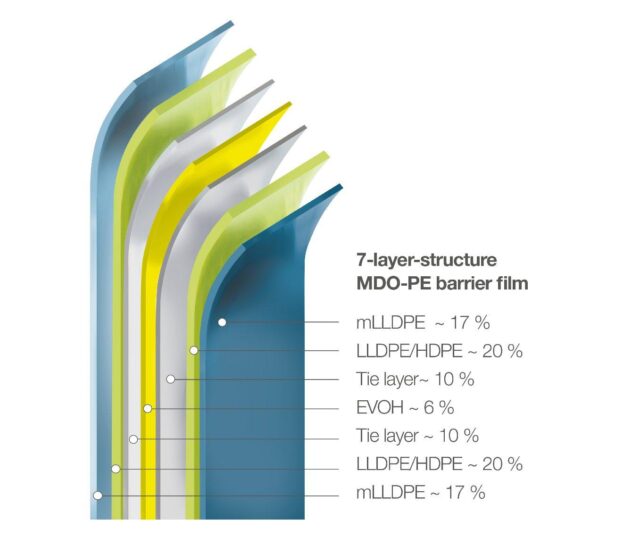

Following the successful introduction of an ultra-thin standard MDO-PE film of only 15µm, SML has now developed a 17µm MDO-PE barrier film to market maturity, featuring the following layer distribution:

The resulting 17µm MDO-PE barrier film is characterised by the following barrier properties, given a stretching ratio of 1:5:

OTR: 1 – 3 cm³/m²/24hr (Oxygen transmission rate at 23 °C; 50 % RH, testing method: ASTM F1927-07)

WVTR: 5 – 8 g²/m²/24hr (Water vapour transmission rate at 38 °C; 90 % RH, testing method: ASTM F1249-06)

Up to 65µm: MDO-PE barrier film for extended application areas

The production of ultra-thin MDO-PE films of the highest quality is by no means the only possible application. The achievable thickness range for fully stretched MDO-PE films goes up to 65 µm, which opens up a variety of other possibilities for film manufacturers. Especially with regard to packaging goods that require higher barrier functions or enhanced mechanical properties,” Elias Mayerhofer continues.

Integrated sealing layer

A further functional advantage of the MDO-PE standard and barrier film is the option to directly integrate a sealing layer. This makes it possible to produce a completely ready-to-use film straight off the cast film line, for example, for products such as stand-up pouches.

Convincing in further processing and printing

Both SML’s cast MDO-PE barrier film and conventional blown MDO-PE film can be further processed with ease on lines for coating and laminating, for example, with the FlexPack system from SML. In addition, cast MDO-PE films exhibit excellent printability and have been successfully tested on both Flexographic and Rotogravure printing systems. Metallisation is possible without any complications, even with ultra-thin MDO-PE films of 17 µm.

To give an example, a 25µm metallised MDO-PE barrier film comes with the following barrier properties:

OTR: 0.30 – 1 cm³/m²/24hr (Oxygen transmission rate at 23 °C; 50 % RH, testing method: ASTM F1927-07)

WVTR: 0.90 – 3 g²/m²/24hr (Water vapour transmission rate at 38 °C; 90 % RH, testing method: ASTM F1249-06)

Multifunctionality increases capacity utilisation

SML‘s cast film lines with an integrated MDO unit were designed to manufacture multiple film types: MDO-PE film as well as MDO-PP, CPE, CPP and Cast-PET film. “The wide range of possible films and very fast product changeovers without the need for technical adjustments allow manufacturers to increase the capacity utilisation and profitability,” Elias Mayerhofer confirms.

Cast technology for unparalleled film quality

Generally, films produced in a cast process attain an excellent level of transparency. A superior film quality is reached through optimum flatness and the ideal distribution of thickness during production. Direct edge trim re-feeding is possible with all film types, even for ultra-thin 15 µm MDO-PE film.

Close collaboration with Dow and Kuraray

For the recent development of the 17µm barrier film, SML joined forces with the polymer supplier and long-term partner, Dow Packaging & Specialty Plastics, who supplied ELITETM resins, and EVAL Europe N.V. (a Kuraray company), who provided the best-in-class EVALTM oxygen barrier. “The close collaboration with such competent and experienced partners marks a significant step towards sustainable, high-performance flexible packaging solutions,” concludes Elias Mayrhofer.