For most of history, humans used flames to generate light. Eventually, they discovered that a super-heated metal element in a light bulb could produce useful illumination, only for this technology to be superseded by the LED.

One common feature unites all these forms of light: each is a single light source which throws a more or less homogeneous beam of light over a broad field of illumination. This leaves very little freedom to control the direction of the beam: LED light can be controlled more than light bulbs or candles, but lenses or reflectors can shape even an LED’s beam only to a limited extent.

A turning point in the history of illumination

Now, thanks to a series of design and manufacturing innovations made by ams OSRAM, a turning point in the history of illumination has been reached. The development of a light source in the form of an array of extremely small LEDs – devices one-tenth of the diameter of a human hair – has produced a new kind of illumination: not light as a block or beam, but rather a matrix of thousands or millions of tiny point sources (pixels), each controlled by a digital stream of data that can constantly reconfigure the matrix’s light output millisecond-by-millisecond.

It’s a new paradigm for light generation, and it is the foundation of a new concept that the company calls ‘digital light’.

Breakthrough in semiconductor technology

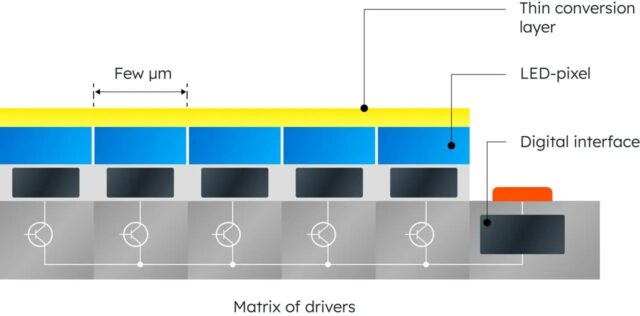

The idea first came as long as 20 years ago: to make a high-resolution projection light source with a new type of LED chip formed of an array of micrometre-scale points of light. But to divide the semiconductor area of a conventional square millimetre LED chip into a matrix of thousands of just a few micrometres sized light-pixels called for a series of technical breakthroughs in basic physics, in semiconductor fabrication, and in materials science.

In addition, ams OSRAM had to develop a new chip architecture, as well as a pixel-level bonding technology to enable it to create a connection between each LED pixel and its driver in a single integrated device. Together, these innovations enabled ams OSRAM to realize the concept of the monolithic microLED array.

MicroLED array hits the road in new high-performance projection headlamps

The resulting technology is now in volume production. The first LED pixel arrays from the ams OSRAM factories are being built into a radically new light source for adaptive driving beam (ADB) car headlamps, the EVIYOS system. The first commercial customers for the EVIYOS chip are car manufacturers, which are building advanced headlamp designs containing a 240×80 pixel array of individually controllable LED pixels. This application of digital light will have a profound effect on safety, and on the driver’s enjoyment of night driving, as well as provide new scope for signalling to the driver and other road users.

Pixel-by-pixel digital control of the light means that the headlamp can operate safely in a permanent high-beam mode. Drawing on camera inputs about the position of oncoming vehicles and of other road users such as pedestrians on the sidewalk, the EVIYOS-based headlamp can turn off pixels that would dazzle others, while maintaining the maximum illumination to light up the road ahead of the driver. Pixel control is adjusted dynamically every fraction of a second to maintain the widest and longest possible beam without compromising the vision of other road users. This adds greatly to the driver’s comfort, and to the safety of all road users.

EVIYOS LED-based headlamps will also project messages and information onto the road. For instance, a potential use for microLED headlamps is to project guidelines marking the area of road that the vehicle will occupy: the headlight shows the driver whether their car will fit through a narrow space or guides the vehicle through complicated arrangements such as temporary roadworks.

Transparent displays and micro-projectors transform technology product designs

But the possibilities of digital light go far beyond illumination. For instance, microLED pixels are so small that they can be embedded in a transparent display screen – and still produce a sharp, clear image. Early uses of this transparent display capability could be in the rear window of cars, where it could display signals and warning messages to the vehicle behind.

The transparency of a microLED display is the result of the wide spacing of the micrometre-scale points of light – in a high-resolution TV, the array of RGB microLEDs might occupy as little as 0.5% of the total display area. The large gaps between the microLEDs also give scope to add other microscopic components such as a distributed camera or infrared sensors, turning it into a multi-function display that can also offer gesture sensing, proximity detection and other features.

Micro-pixel arrays with tiny pixel sizes are also an essential element of the next generation of augmented and virtual reality (AR/VR) equipment. In smart glasses, for instance, a microLED display could be embedded as a micro-projector, providing an unobtrusive method for layering AR information onto the wearer’s view of the scene. Proofs-of-concept show that more than 2 million individually addressable LED pixels, each with an edge length of approximately 1μm, can be embedded in a one-pixel array to provide the wearer of smart glasses with images in full HD resolution.

Beyond these projection systems, digital light offers new value in many other applications – 3D printers, for instance, will be able to perform ultra-high resolution curing, enabling them to build more precise and intricate structures.

And in data centres for artificial intelligence (AI) applications, the use of digital light promises far more efficient high-bandwidth optical communication. Today’s high-speed optical communication links use a laser light source switching at very high frequency to send serial streams of data down a fibre optic cable. The use of microLED arrays – in which the LED pixels are hundreds of times smaller than a laser light source – offers the potential to send data in parallel rather than serial, giving far more efficient bandwidth and helping to reduce the energy footprint of power-hungry data centres.

Embedded light wherever you imagine it

The development of light sources made of individually addressable pixels required a monumental effort over a period of more than 10 years and involved contributions not only from ams OSRAM but also industrial partners such as the Fraunhofer Institute for Reliability and Microintegration IZM in Berlin, backed by government and European Union funding. The successful realisation of the vision for flexible, digitally addressable light required not one but many separate technical breakthroughs. This optical technology is completely and truly novel, and this means that all the uses for it cannot yet begin to be imagined. The first use case – for ADB headlamps that transform the driving experience at night – is just one example of the value that microLED arrays can bring: there are many more to come.

The ability to open up new horizons for products across the industrial, consumer, automotive and other markets is the exciting consequence of committing talented people and the combined industrial and scientific capabilities of multiple organisations in pursuit of a huge and important breakthrough.