Canatu and DENSO have started up their new, jointly developed carbon nanotube reactor at the Canatu factory in Finland. The new high-performance reactor was developed to scale-up carbon nanotube film manufacturing to meet increasing demand to address global ADAS (Advanced Driver Assistance Systems) market with more competitive products. Through this development, Canatu and DENSO can triple the throughput of Canatu carbon nanotube (Canatu CNT) films while maintaining record-high performance.

Carbon nanotubes hold immense potential. Their unparalleled properties are increasingly suitable for a range of applications. However, one key obstacle impeding the widespread application of carbon nanotubes in future products is the challenge of controlling their growth and variation during mass production. Through joint development, Canatu and DENSO have significantly progressed in scaling and controlling the chemistry of Canatu’s proprietary CNT synthesis process. This enables large-scale production of Canatu CNT films with consistent quality for highly engineered solutions.

Product quality and stable supply chains

“Product quality and stable supply chains are the most important things in the automotive business and what we DENSO always give top priority. We are very excited about the achievement of our joint team. We believe this significant step will make our product more valuable and competitive,” stated Toshihiko Muraki, Head of Passenger Vehicle Business Unit of Thermal Business Group, DENSO.

“Canatu has highly developed expertise in CNT film manufacturing through experience in mass production since 2015. We have fine-tuned our own process to ensure consistent quality. With the new high-performance reactor, we will take a giant leap forward in industrial-scale carbon nanotube film manufacturing, benefiting customers with cost-competitive products,” explained Taneli Juntunen, Vice President, Engineering, Canatu.

The joint development programme focused on improving the reactor design, process controls and serviceability. Key design changes included sizing up the reactor and its components and implementing a novel, parallel furnace design to multiply the synthesis process yield. Optimal carbon nanotube growth conditions to maximise yield were realised through modular reactor prototypes and system-scale simulations. The new reactor cluster is equipped with in-situ monitoring of carbon nanotube growth, and a new collection chamber design, that together ensures low ADAS heater-to-heater variation. For customers, this means consistent quality in terms of product uniformity. Finally, thanks to improved serviceability, the operating rate target of 90% has been achieved, with service time reduced to 4 % of operating time.

Reactor platform

The newest reactor will be expanded into a reactor platform for next-generation carbon nanotube products. High-performance reactors are now integrated into the fully automated roll-to-roll Canatu CNT film manufacturing line and deployed during mass production. Canatu CNT film throughput can be further scaled by integrating up to four additional high-performance reactors into the step-and-repeat film manufacturing line.

Canatu focuses on creating the most advanced carbon nanotubes for highly engineered solutions, where optoelectronic performance and reliability are crucial. Under the automotive industry, Canatu advances autonomous driving in any weather with Canatu CNT film heaters for ADAS cameras and LiDARs. Additionally, Canatu’s 3D touch sensors shape surfaces into experiences in automotive interiors, enabling design freedom and an intuitive user experience. Today, Canatu is in mass production through eight programsme.

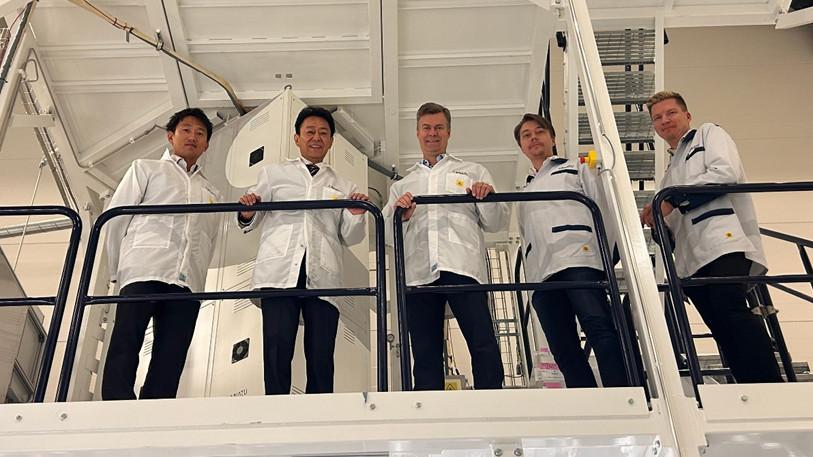

Caption: Yoshiyuki Yokoyama (DENSO), Toshihiko Muraki (DENSO), Juha Kokkonen (Canatu), Taneli Juntunen (Canatu) and Antti Valkola (Canatu)