Researchers from EPFL, Empa, and CSEM have developed a sustainable smart sensing tag that can be used to signal when shipments of medicines or food have exceeded a safe threshold temperature. It is the first such tag to be fully compostable.

Vast flows of goods circle the globe every day. They include particularly delicate shipments, such as certain vaccines, medicines and food products. To ensure that these products arrive safely at their destination, they must remain within a certain temperature range throughout the entire supply chain. But it is costly and unsustainable to equip every shipment with silicon-based sensors and wireless chips.

Project GREENsPACK

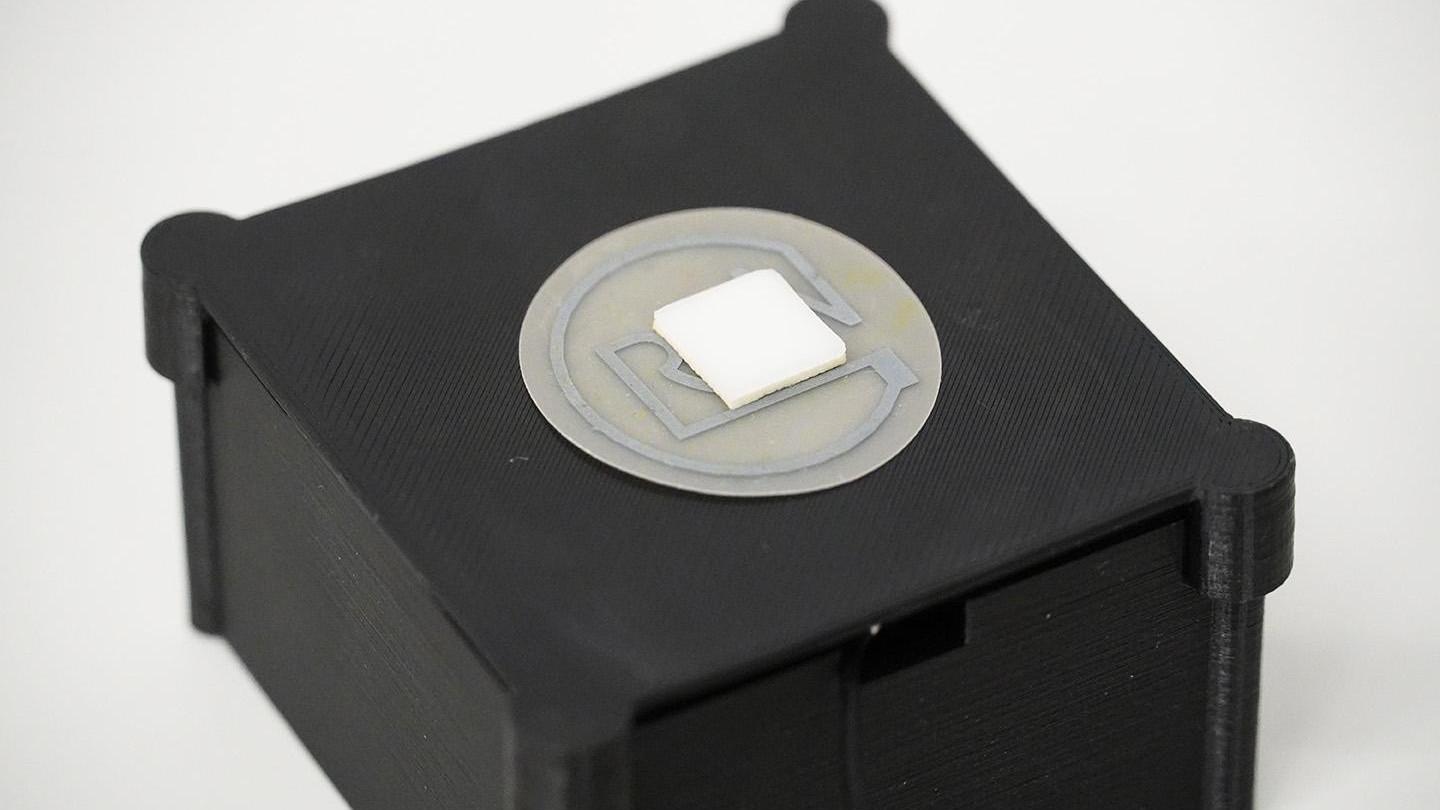

Researchers from EPFL, Empa, and CSEM have taken up this challenge in a four-year project called GREENsPACK. Together, they have developed a wireless, chipless, printed smart sensor tag that can detect whether a certain temperature threshold has been exceeded. The small sticker is silicon-free and made of biodegradable materials. The project was funded by the Swiss National Science Foundation (SNSF) and Innosuisse as part of the BRIDGE Discovery programme.

“Our smart tag can support a sustainable Internet-of-Things, from materials selection to waste minimisation via additive manufacturing, to end-of-life composting,” says Danick Briand of the Soft Transducers Laboratory (LMTS), led by Herbert Shea, in EPFL’s School of Engineering. Briand is co-author on a paper describing the device that has recently been published in Nature Communications.

Sustainable circuits with a memory

The LMTS team fabricated the sensor on top of a composite substrate of biopolymer and cellulose fibres developed at Empa, based on a design and readout technology developed at CSEM. To do its job, the tag needs neither a battery nor a silicon chip transmitter. Instead, it is based on a wireless electrical resonator made of highly conductive and stable zinc tracks protected by a natural wax. If these circuits are exposed to an electromagnetic field, for example from a wireless tag reader, a resonance is created that the reader can decode. If the threshold temperature is exceeded, a solid bio-based oil melts over the circuit, changing this resonance. The next time the label is read, it shows: this shipment was once too warm.

Different temperature thresholds can be set depending on the type of oil used, including frozen olive, jojoba and coconut oils, which melt at different temperatures, triggering irreversible resonance frequency shifts. Once melted, the oil is absorbed by a cellulosic material placed underneath, which allows the tag to operate reliably at different inclination angles.

LMTS researchers and co-authors James Bourely and Nicolas Fumeaux say they hope their technology can help fight the rising environmental concern of electronic waste. “In 2022, the world produced 62 megatons of e-waste – the equivalent of 16 Eiffel towers per day – with only 22% of that properly recycled. Our work represents a green technology platform to make sustainable printed circuit boards and therefore reduce electronic waste.”

Written by Celia Luterbacher, School of Engineering, STI