FLEXOO GmbH, a leader in advanced printed electronics for battery monitoring, will present its groundbreaking in-situ cell monitoring technology at the ees (electrical energy storage) exhibition. The ees is a specialised trade fair focusing on energy storage solutions as part of The smarter E Europe (7-9 May 2025), the continent’s largest platform for the energy industry, taking place in Munich. Visitors can find FLEXOO at Hall B0, Stand 135.

Advanced BESS cellular monitoring prevents catastrophic battery failures

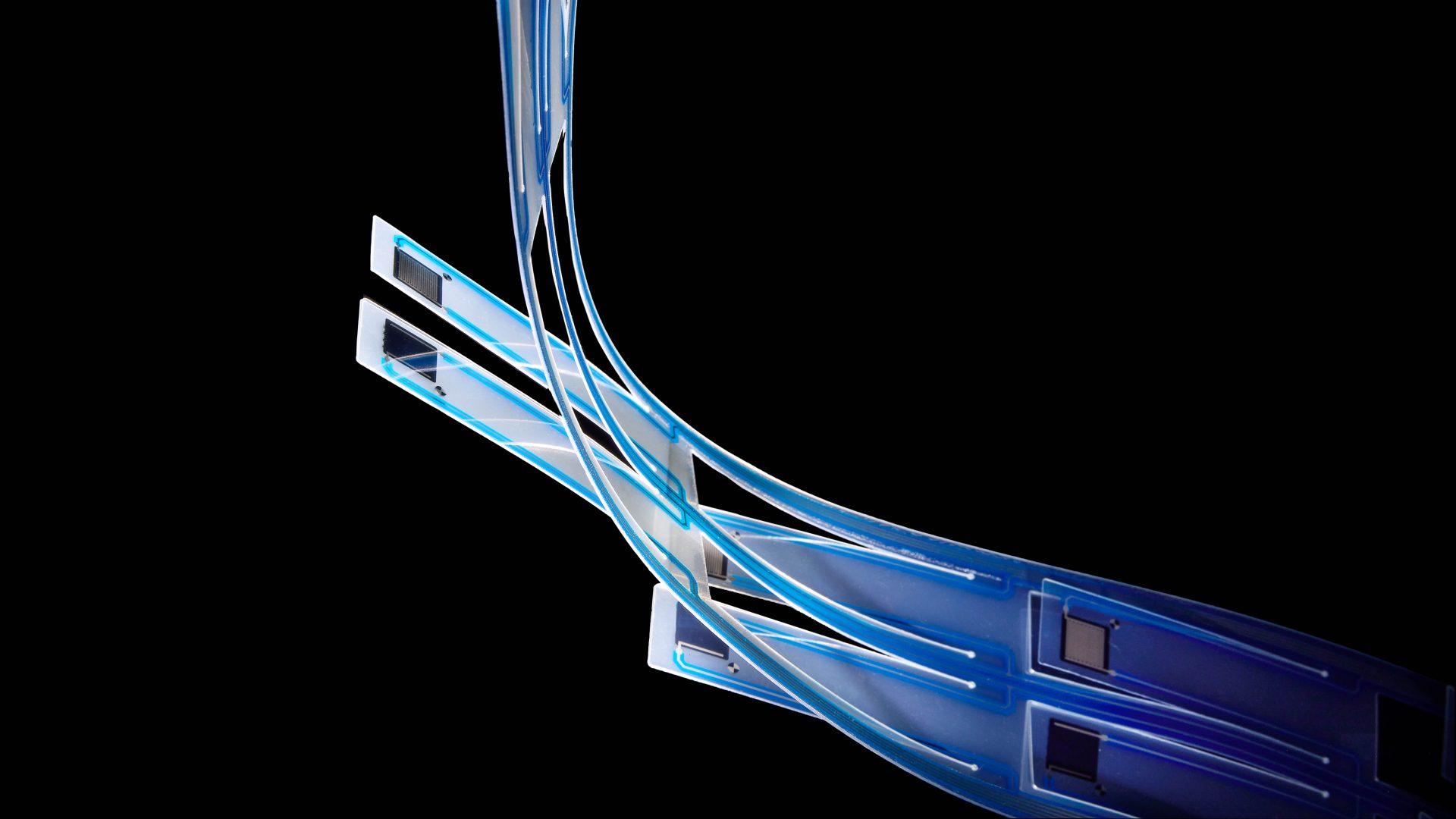

FLEXOO’s ultra-thin printed sensors address the critical safety challenges facing Battery Energy Storage Systems (BESS) by detecting thermal anomalies at their source – directly between individual battery cells. This breakthrough technology enables early identification of potential thermal runaway conditions before they can cascade into dangerous failures. Safety begins where the risk originates: at the cell level of each individual battery in the pack. FLEXOO’s high-precision sensors fit seamlessly between cells, providing real-time temperature and pressure data that gives operators a crucial time advantage.

Next-generation BESS safety technology

At the ees exhibition during The smarter E Europe 2025, FLEXOO will demonstrate how its wireless sensors integrate into battery packs without altering their design. These printed sensors on flexible films measure with high precision in real-time, transmitting critical data directly to Battery Management Systems.

The technology delivers compelling benefits:

- Enhanced safety through early detection of hotspots

- Extended battery lifespan (up to 40%) from optimised operating conditions

- Increased efficiency and maximised energy yield

BESS cellular monitoring applications span multiple industries

FLEXOO’s cellular monitoring solutions are suitable for various applications, including:

- Stationary storage for renewable energy

- E-mobility battery systems

- Industrial UPS applications

- Consumer electronics

Visitors to FLEXOO’s stand will see firsthand how the company’s expertise in printed electronics creates the most precise printed sensors available for battery monitoring.