Meech International, a global leader in static control and surface cleaning technologies, has announced a new distributor agreement with EMEA Electro Solutions, expanding its footprint across Spain and Portugal. The move comes ahead of Labelexpo Europe 2025 (16–19 September, Barcelona), where Meech will share new insights into safe and efficient RFID label production and showcase its latest innovations in static management.

In RFID label production, static levels on materials can reach thousands of volts – more than enough to instantly damage chips that are vulnerable even at 100 volts. These invisible charges are a hidden threat, silently causing chip failures, yield losses, and costly rework.

Static charge at multiple points along the production line

In one instance, Meech’s engineers monitored static charge at multiple points along the production line, identifying levels 22 times higher than safe limits for chip handling. The manufacturer was experiencing high failure rates during chip insertion, leading to significant yield losses.

By deploying ionising bars in combination with smart controls and feedback sensors, static charge was reduced to just ±3 V and stabilised well within the ±35 V industry benchmark for safe RFID insertion. The result was a more than 50% improvement in yields, transforming profitability and enabling the manufacturer to meet their customers’ high-volume demand without having to over-produce to offset anticipated losses.

“Even a small static charge can silently and rapidly erode yields,” said Ian Atkinson, Sales Director at Meech. “An ever-present risk is latent defects: a chip might pass initial testing but fail further down the supply chain, creating costly tracking failures. Rigorous static control is critical to ensure these sensitive components are consistently protected so that every label remains reliable in the field.”

New distributor agreement boosts reach in Spain and Portugal

Meech’s new distributor agreement with EMEA Electro Solutions will help bring these advanced static management solutions to more manufacturers across Europe. Under the agreement, EMEA Electro Solutions will offer Meech’s full portfolio of static control and web cleaning technologies to businesses in Spain and Portugal, supporting labelling and packaging manufacturers as well as customers in other industrial sectors.

“EMEA Electro Solutions shares our focus on technical excellence and customer support,” Atkinson remarked. “Their background in microelectronics and battery manufacturing and presence in Spain and Portugal means they are ideally placed to support local converters embracing smart labelling technologies with direct access to expert solutions and support tailored to regional production challenges.”

“We’re seeing growing demand from Iberian manufacturers for smarter, more reliable solutions to static and contamination – especially as adoption of RFID and other smart labelling formats increases. Joining with Meech allows us to offer customers proven technologies to directly address these challenges,” said Jose Luis Pardo, CEO of EMEA Electro Solutions.

Labelexpo Europe 2025 exhibitor highlights

Meech will join together with EMEA Electro Solutions on Booth 5G71 to showcase advanced static management and surface cleaning solutions, including:

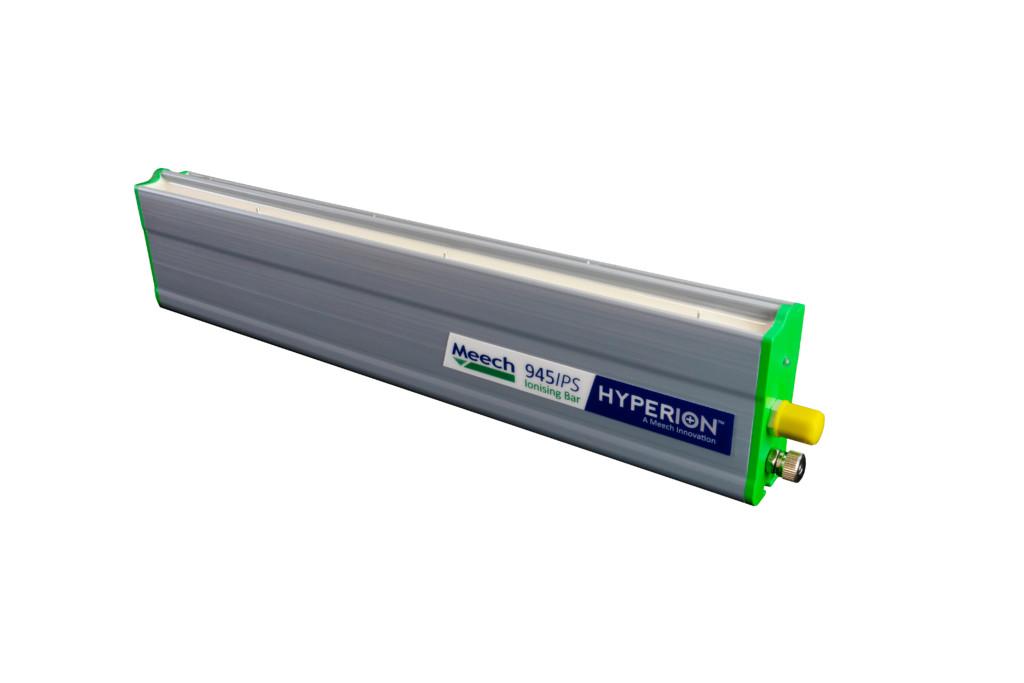

- The new Hyperion 945IPS Mid-Range Ionising Bar launched earlier this year to improve safety and quality for mid-range applications

- Hyperion 650QAC Quasi AC Ionising Bar, designed for ESD-sensitive applications such as label printing with integrated RFID chips

- A range of contact and non-contact web cleaners and smart control systems for labelling, flexible packaging and converting applications

Atkinson continued: “Labelexpo is a key platform to demonstrate how our technologies drive productivity, efficiency and quality in labelling and packaging. We are especially pleased to be exhibiting alongside EMEA Electro Solutions, who strengthen our presence in Spain and expand our reach into Portugal, giving manufacturers the local support and deep technical insight they need to optimise line performance.”