PRO Flextronics sat down for an interview with Michael Schläfli, CEO of nsm, which is based in Zofingen, Switzerland. His company offers an extensive portfolio of printing, coating and laminating equipment, with a special emphasis on pushing the boundaries of innovation in printed electronics.

Mr Schläfli, your company nsm has been exhibiting at LOPEC for many years and is known as a leading machinery supplier for printed electronics. Please introduce us to your products and services – and provide us with an overview of your capabilities!

Michael Schläfli: NSM Norbert Schläfli AG is a Swiss machinery manufacturer specialising in printing, coating and laminating systems for printed and flexible electronics. For many years, we have been supporting research institutes, universities and industrial partners worldwide with highly precise lab and pilot-scale equipment.

Our portfolio ranges from compact benchtop R&D systems to modular roll-to-roll and sheet-based pilot lines. Customers can combine multiple printing technologies such as gravure, flexographic, rotary and flatbed screen and coating processes within one platform, serving applications in printed electronics, functional materials and emerging energy technologies, including perovskites.

Our strength lies in flexible, customer-specific solutions, high reproducibility and a deep understanding of functional materials and multilayer processes.

Perovskites are a promising market segment for players in the flexible and printed electronics sector. What must be considered when dealing with these materials – and how are these considerations reflected in your machine designs?

M. Schläfli: Perovskite materials are highly sensitive to process parameters such as temperature, atmosphere, layer thickness and drying behaviour. Achieving stable and reproducible results therefore requires very precise control over coating, drying and handling steps.

These requirements are directly reflected in our machine designs. NSM systems focus on controlled and reproducible process conditions, gentle material handling and accurate layer deposition. Modular machine concepts allow users to adapt coating, drying and curing steps to the specific needs of their perovskite material system. Our machines are designed to support systematic process development and to enable a reliable transfer of perovskite processes from laboratory scale to pilot production.

Speaking of Perovskites, nsm’s explorer 801 is a dedicated machine concept for this segment. Please introduce us to the technological highlights of this machine!

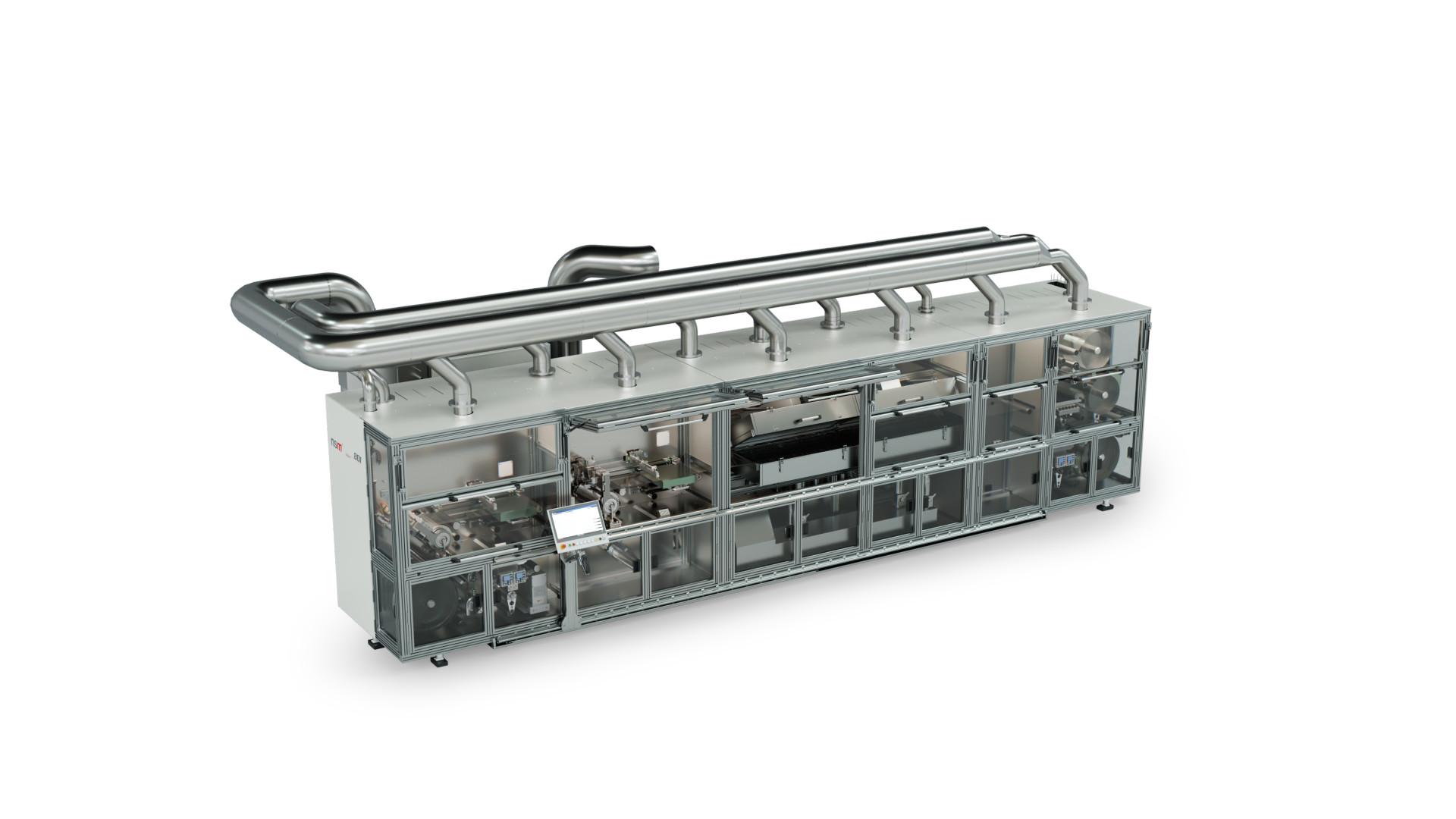

M.Schläfli: The Explorer 801 is a dedicated machine concept specifically developed for perovskite-based applications. It is designed to enable precise and reproducible deposition of functional layers under well-controlled process conditions.

Key technological highlights include its modular architecture, allowing the integration of different coating and printing technologies, as well as tailored drying and curing concepts. Stable substrate handling and accurate process control ensure excellent layer uniformity and reproducibility, which are essential for perovskite device development.

With the Explorer 801, users can systematically develop perovskite processes and prepare them for scalable pilot production.

The Challenger 650 is one of NSM’s long-established sheet-based platforms for printed electronics and functional materials, complementing the roll-to-roll Explorer 801. What are the key characteristics of this system and where do customers typically use it?

M. Schläfli: The Challenger 650 is a modular, high-precision sheet-based platform that has been successfully used in printed electronics research and pilot production for more than ten years. It is designed for applications that require excellent layer accuracy, reproducibility and process flexibility.

The system supports a wide range of printing and coating technologies, as well as drying, curing and lamination processes. An integrated camera alignment system enables accurate multilayer registration, which is essential for many printed electronics applications.

The Challenger 650 can process both flexible and rigid substrates up to 300 × 300mm. With process speeds reaching up to 90m/min, the system clearly moves toward production-relevant conditions. Customers typically use the platform in printed electronics, functional coatings and energy-related applications, including fuel cells, where reliable process development and scalable concepts are essential.

In just a few days from now, we will meet you again as an exhibitor at LOPEC 2026. What are you going to showcase in Munich – and who should visit your booth?

M. Schläfli: At LOPEC 2026, we will present selected machine concepts and application examples related to printed electronics and energy-related technologies, with a focus on the Explorer 801 and the Challenger 650. Our booth is aimed at researchers, developers and industrial partners working on functional materials, perovskites and scalable manufacturing concepts.