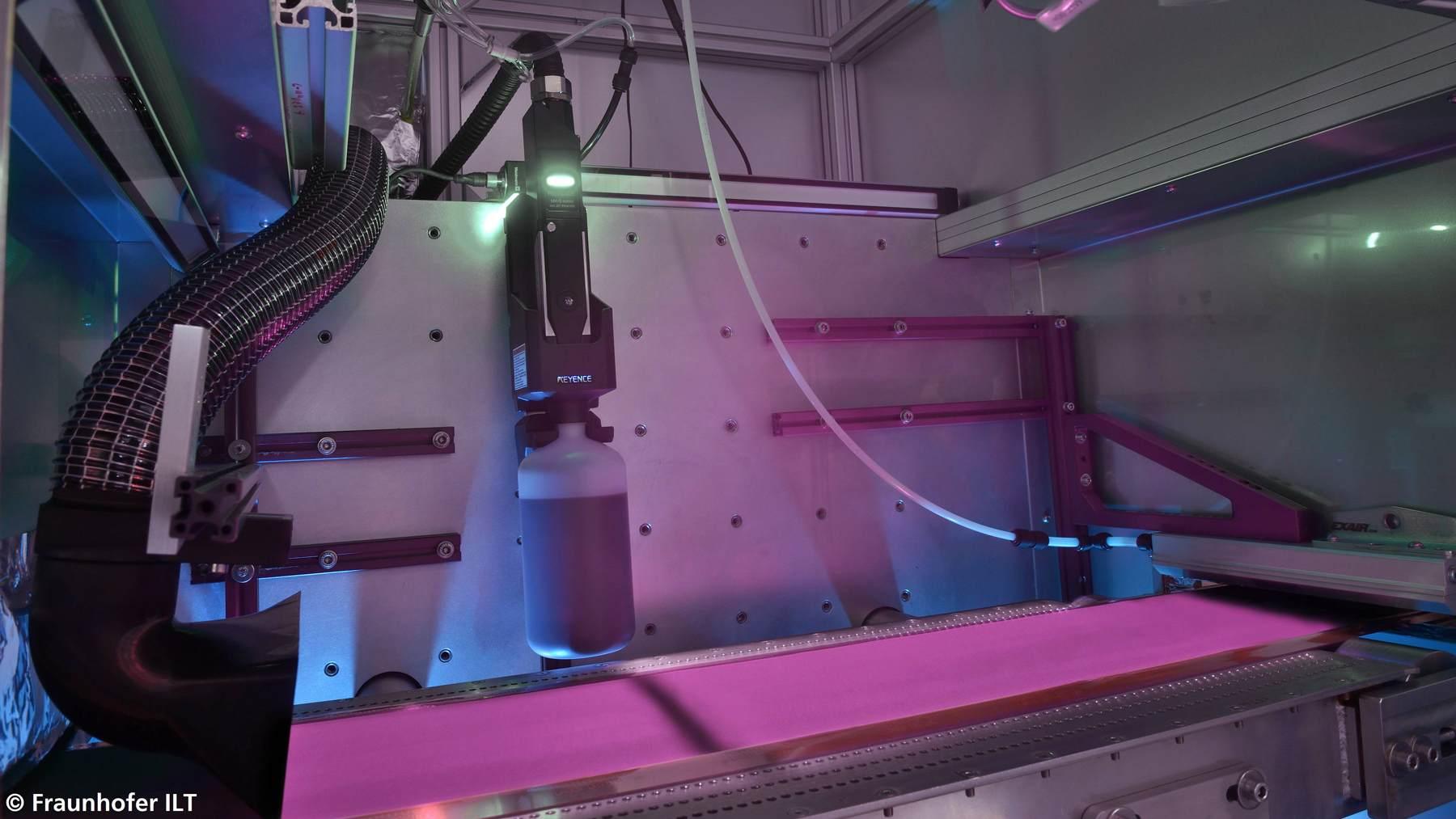

As part of the IDEEL research project, Fraunhofer ILT has succeeded for the first time this year in scaling up the laser drying process in an R2R (roll-to-roll) system from Coatema GmbH to a web speed of 5 m/min and demonstrating 2-stage laser drying.

This doubling of the web speed (compared to the previous year) was made possible using laser beam sources and drying optics specially developed for the requirements of laser drying by Laserline. High-precision thermal cameras from Optris in combination with a laser power control system specially developed for this process ensure homogeneous drying. In combination with the short response time of the laser beam sources applied, this control concept enables highly dynamic process control. Furthermore, the thermographic images also enable reliable detection of defects in the electrodes – such as variations in layer thickness or unwanted particles in the layers.

Optimising the drying and coating process

At the same time, the research and development team of the coating machinery company Coatema optimised the drying and coating process using CFD (computational fluid dynamics) simulation to further improve the resulting electrode quality. The focus here was on improving the design of slot die geometry for the electrode coating process. In addition, the prototype laser drying unit with optimised air flow was recently realised at Coatema in Dormagen. This year, the laser optics developed by Laserline will be integrated into the system and the further upscaling of the drying process (up to 30m/min) will be tested in the R&D Center of Coatema using high-power diode lasers.

Reducing the drying time for LFP cathodes

Furthermore, the project partner PEM, Chair of Production Engineering of E-Mobility Components at RWTH Aachen University, has succeeded in reducing the drying time for LFP cathodes and graphite anodes by over 60 percent – and thus significantly reducing the energy requirement and CO2 footprint as predicted. To further develop the process in terms of materials, the partners at MEET (Münster Electrochemical Energy Technology) Battery Research Center at the University of Münster are currently working on new types of silicon-containing anodes to increase the performance of the batteries. These new developments are being tested for compatibility with the laser drying process in close collaboration with researchers at PEM and the Fraunhofer Institute for Laser Technology ILT, and any necessary adjustments are being made as required. Additional surveys conducted by the Fraunhofer Research Institution for Battery Cell Production FFB among users from industry and research also continuously provide new data on the current requirements for drying processes. Thus, enabling application-oriented development work. This comprehensive consideration of the overall system consisting of machinery technology, process and material development not only allows the project participants to implement and demonstrate the process close to industry, but also makes it possible to drive forward the currently rapidly changing battery production sector in Germany.

Caption: Innovative process technology enables energy-efficient drying of anodes and cathodes while at the same time reducing space requirements