With drupa, the world’s largest trade fair for printing technology will take place in Düsseldorf from 28 May to 7 June 2024. In hall 16 on stand C20 under the motto “Creative automation – our solutions for your excellence”, Erhardt+Leimer GmbH will exhibit its new components for web guiding and web tension control, web monitoring and inspection.

Among other products, there will be new gearless, linear and rotary synchronous drives. Visitors will also be able to familiarise themselves with the numerous advantages of the data management software ELQ, using which production processes can be centrally operated, controlled, analysed, optimised and documented. E+L specialises in automation and inspection technology and has an international sales and service network.

The drive for Industry 4.0

Clear technical challenges are currently emerging in machine tool manufacture and mechanical engineering: the need for modernisation, simplification and standardisation. At the same time, there is also a demand for extreme flexibility and agile processes, i.e. fast turnaround times combined with great ability to adapt to ever-changing requirements. These opposing demands are often faced by engineering departments that already tend to be overworked, frequently resulting in conflicting goals during implementation. Drive technology is an essential driving force in all production setups, so when it comes to reconciling the technical conditions with the day-to-day reality of the production environment, it plays a central role. Erhardt+Leimer is tackling these challenges with its state-of-the-art drive concept EL.MOTION, which is setting new standards for Industry 4.0.

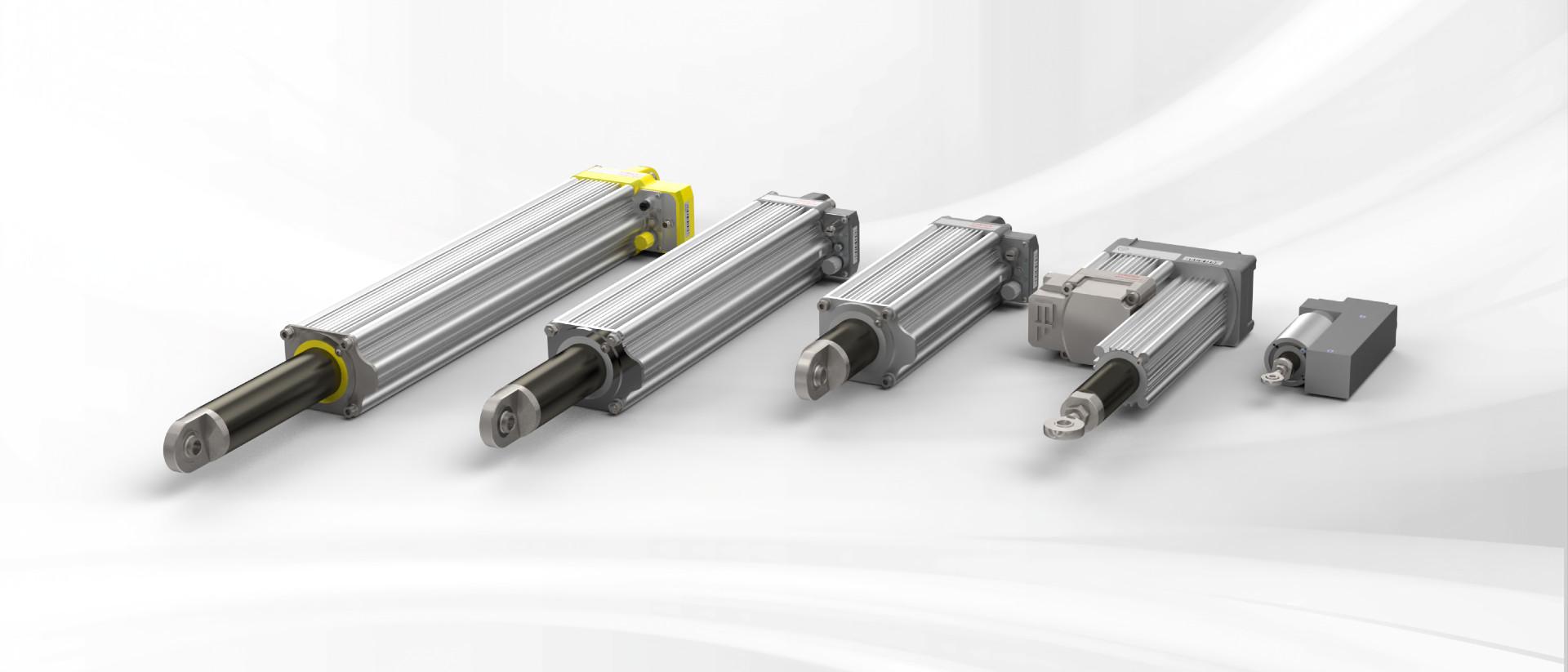

EL.MOTION includes a wide selection of gearless, linear and rotary synchronous drives. The pioneering innovation of EL.MOTION is that the existing BLDC machines in this performance class can now be replaced with synchronous machines. This opens up the ability to deliver the same highly dynamic performance and excellent control capability we are familiar with from gearless drives in a much smaller package. Despite the small form factor, fully integrated power electronics with a power-failure-proof encoder system are already integrated in the system. The motors can be commissioned and put into operation using any browser via the web-based management tool. With a standard integrated Ethernet interface that supports Ethernet UDP, EtherNet/IP, and Profinet, all drives can be seamlessly integrated into existing production processes and are perfectly suited to Industry 4.0 concepts.

Linear and rotary drive units

The linear drive units AG 72, AG 91, AG 93, and AG 96 are synchronous motors with high positional accuracy and control dynamics. The nominal actuating forces of the relevant motors are in the range from 250 to 5500 N at a feed rate of up to 60 mm/s. The linear drive units are specially designed for long-term use and are therefore excellently suited to numerous applications. The rotary drive units AD 11, AD 12 and AD 14 are synchronous machines with a high power density. With very compact component dimensions, these motors achieve a torque output in the range from 1 to 4 Nm at speeds between 230 and 1000 rpm, offering a gearbox-free solution for many applications. High axial loads can also be handled without problems thanks to the additional support provided by a two-row angular contact ball bearing. As a result, the drive units can be connected directly – without a coupling – to a machine, which makes them very easy to integrate into existing production lines.

Functional safety by means of “Safe Torque Off” (STO)

The safety function STO in accordance with EN 61800-5-2 is an optional addition to Erhardt+Leimer drive units. This safety feature, which is integrated in the drive, switches off the motor torque by interrupting the control pulses.

New generation of SMARTSCAN 200% print image inspection

The new generation of SMARTSCAN can be installed in the familiar way on printing machines and rewinders. SMARTSCAN – or the MIS2 model to be more specific – is now faster and more compact, and it has a new design. On the variant with 2K resolution, we have already been able to achieve speeds of up to 600 m/min. But the 4K variant is catching up, and is now reaching speeds of up to 400 m/min. Faster LEDs and an optimised lighting concept deliver even better image quality. The reflection module for displaying reflective, usually metal-coated materials or finishing foils (e.g. gold, silver) is now included as standard. The same applies to the exchangeable background panel, which is advantageous for transparent materials in particular. With this package, users can trust that they are playing it safe in most areas, e.g. for label or packaging printing. The height of the camera units has been significantly reduced – but no compromises have been made in terms of the standard functions such as the integrated lighting on the rear panel or the roller guidance. A new installation concept makes integration in the printing machine or the rewinder even easier. Previously, SMARTSCAN was available with a maximum width of 560 mm (22 inches), but with the latest generation, E+L now also offers 660 mm (26 inches) and 760 mm (30 inches). In addition, the software has been optimised and expanded. New defect detection algorithms spot defects with even greater reliability. The same applies to the defect classification system, which assigns defects to categories such as missing labels, unremoved matrices, print errors, glue joints or flags even more reliably than before. Further defect classes such as hole, barcode or incorrect length are also available. With all these options for capturing defects and errors, comprehensive evaluations can be performed in order to understand and optimise production processes. The tried and tested 200% inspection technology will, of course, continue to be used. Improvements have also been made to the detection of hole defects and to the illumination of fluorescent materials. However, special applications, such as the production of labels with integrated RFID antennas, will also benefit from the new features.

An as yet unspecified new product will also be presented “exclusively” for drupa visitors at the E+L stand.

https://www.erhardt-leimer.com

Caption: Linear and rotary drives from the EL.MOTION product family