Drupa, known as the world’s leading trade fair for printing technology, is once again at the centre of the industry, and INOMETA is ready to impress the printing industry with innovations. Specialising in flexographic printing rollers and sleeves, INOMETA has made a name for itself for developing products that significantly improve performance and quality in the printing process.

The two latest developments from INOMETA once again promise to set new standards in flexographic printing

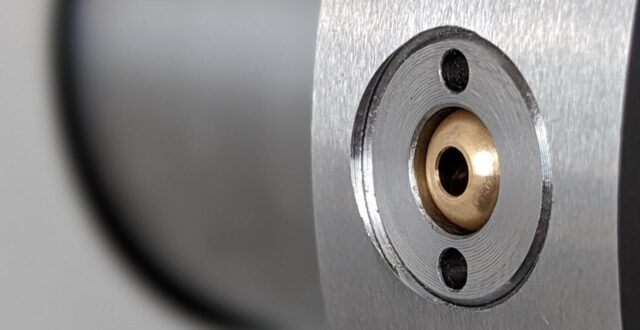

The innovations in flexographic printing, such as the INOlink system from INOMETA, clearly demonstrate how technology and sustainability can go hand in hand. INOlink, a patent-pending air supply system, aims to minimise compressed air consumption during the sleeve process, thereby reducing operating costs and CO2 emissions. This reduction not only contributes to cost efficiency, but also promotes more environmentally friendly production. The reduction of noise emissions through INOlink improves working conditions and increases employee safety. As part of the INOflex product family, renowned for its reliability and innovation, INOlink offers companies a valuable opportunity to optimise their production processes while improving their environmental footprint. The flexibility with which INOlink can be integrated into new and existing printing systems makes it a versatile solution to the challenges of the modern printing industry. INOlink is part of the INOflex family, which is already recognised and established for its reliability and innovation in the flexo printing market.

With INOid, INOMETA is setting a new standard for access to product information and enhanced services to help its customers overcome their operational challenges

Fast access to product information is crucial for the efficient management of web guiding machine components. Incorrect information or delayed access to data can lead to errors and delays in the production process. For this reason, INOMETA has developed INOid® – a platform that enables access to product-specific information by simply scanning a QR code or RFID tag.

INOid® is a comprehensive platform that enables the user to have all relevant documents such as measurement reports and delivery notes immediately to hand. For products that are not equipped with INOid® as standard, INOMETA offers a simple retrofit option by attaching a QR code or RFID tag. Product and machine-specific services can also be booked via the INOid® app, which further increases the practical customer benefits of INOid®.

Improving the management of web guiding components

The platform is designed to be manufacturer-independent. The growing network of service partners within the app makes INOid® the ideal solution for companies of all sizes that want to improve their management of web guiding components and expand their access to services. With INOid®, INOMETA supports all customers in making their processes more efficient and increasing reliability.

With the INOflex® product family, the system solution for flexographic printing, INOMETA offers a comprehensive lightweight portfolio for use in the printing unit and other areas of printing presses. INOMETA has established itself as an innovation leader in the flexographic printing industry by continuously developing solutions that are tailored to the current challenges and needs of its customers and OEM partners.

Focussing on new industry trends

Specialising in rotating printing unit components, INOMETA develops and manufactures harmonised components such as anilox rollers or anilox sleeves, hydraulic and pneumatic clamping CFRP adapters and CFRP carrier bars. INOMETA is also a leading specialist in the production of web-guiding rollers with functional surfaces and winding cores.

INOMETA is also constantly focussing on new industry trends. For example, INOMETA supports the rapidly growing technology fields of battery production and the manufacture of energy storage systems with rollers and other lightweight components, including customised functional surfaces that can make the production lines in this industry safer, more efficient, faster and more cost-effective.

(Paid Advertorial by Inometa GmbH)