Just over 15 years ago, a compact rewinding machine for aluminium cladding film for insulation technology was delivered to Alujet in Mammendorf, Germany. This marked the beginning of a long-term cooperation with Euromac. Alujet, a renowned supplier and manufacturer of insulation accessories has grown in recent years and with it the variety of its products, which had to be produced on outdated slitting systems.

Modern requirements in terms of reducing set-up time and waste, as well as appropriate ergonomics, led to the decision to invest in a further slitting and winding machine from Euromac. In addition to the development of the technical specifications, it was also possible to run various slitting and winding tests with customer material on existing demo machines at the Italian supplier’s premises in Casale Monferrato. The extremely positive results underlined Alujet’s confidence in their products and they made the decision to procure another machine from Euromac and the responsible sales and project management team, Megapak GmbH & Co. KG from Hilden, Germany. All of this resulted in the delivery of the new machine in summer 2023.

High standards

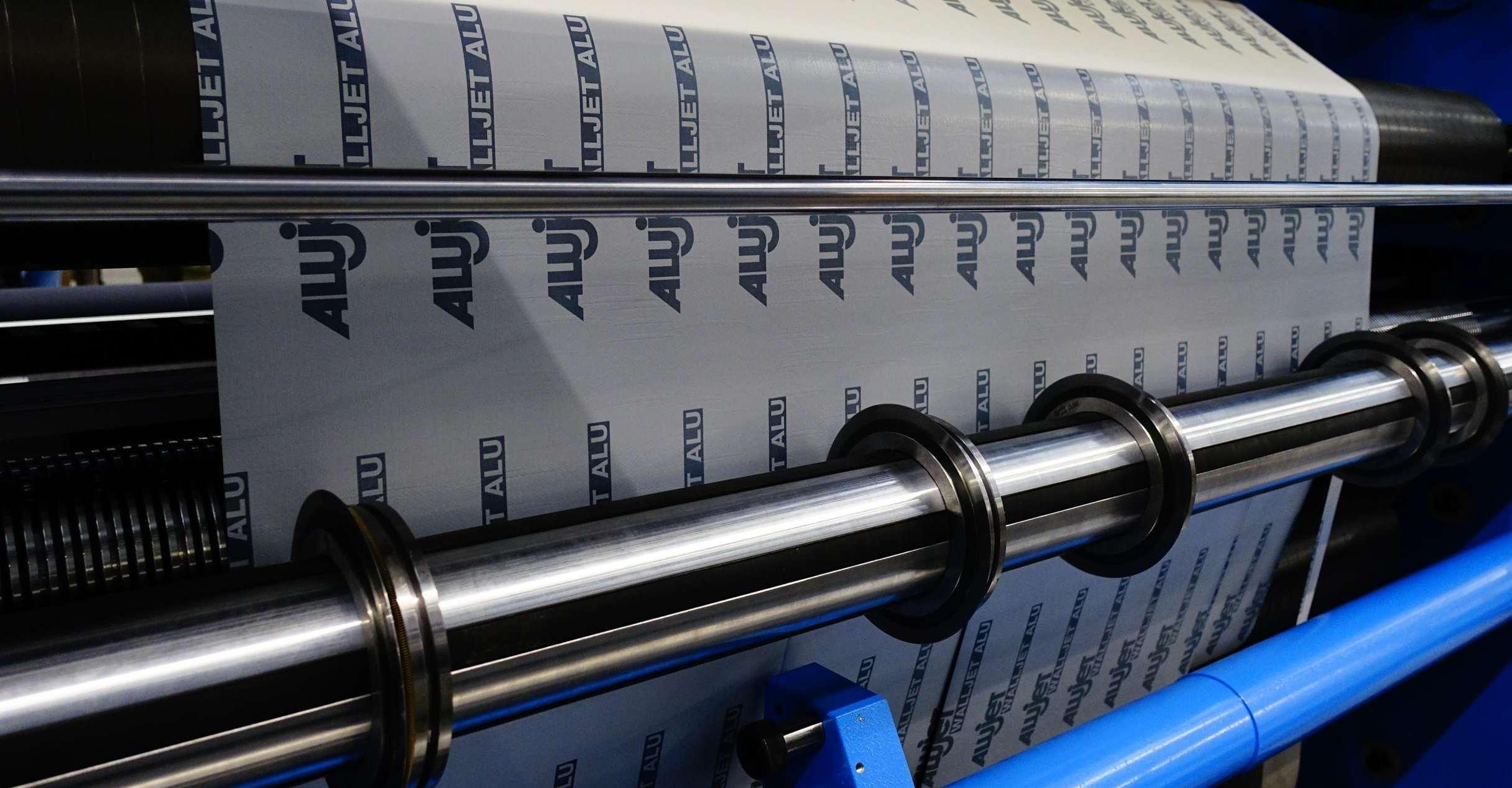

The demands and requirements of the specialist for insulation materials from Mammendorf for the new winder were varied. Aluminium foils up to 300µm had to be slit and wound, various nonwoven materials, e.g. for roof underlays, various composite materials in small and large rolls up to 800mm in diameter with relatively high weights of up to several hundred kg, especially when aluminium materials come into play. The winding of aluminium products on winding axles with a diameter of only 50mm is also part of the daily business. It should be noted that the retooling of the winding shafts to other diameters is carried out using a specially designed set-up and loading trolley, which saves the customer from having to use additional lifting gear.

The Swiss army knife of winders

All these requirements were best met with the extremely versatile 1.5 metre-wide two-spindle machine from Euromac. As usual, this winder was fully assembled and commissioned at the supplier’s factory so that it could be thoroughly tested with the customer’s material. In the presence of Alujet’s energetic team, the successful acceptance and dispatch release took place. Due to the limited space available in the customer’s factory, a customised solution was sought and found for this project – a compact winder that still offers the best possible accessibility and user-friendliness.

The machine is also free of hydraulic oil as standard – the usual functions associated with hydraulic oil, such as lifting the heavy mother rolls, are realised entirely by employing electric motors – an additional plus point in terms of maintenance and cleanliness around the entire machine.