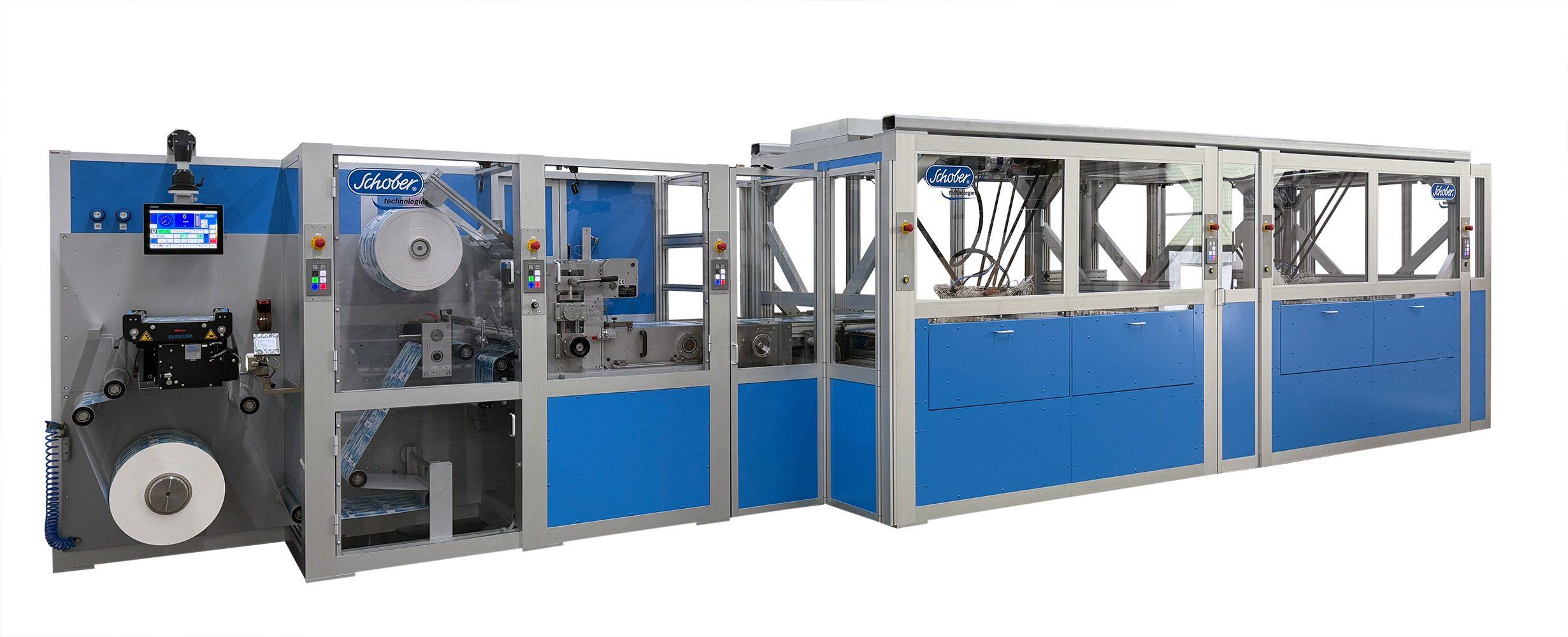

Schobertechnologies GmbH is a leading specialist in the development, design and manufacturing of high-quality rotary cutting, creasing and punching equipment. From the development to production, assembly, commissioning and worldwide after-sales service, Schober’s focus is always on the perfect workflow for its customers. According to Schober’s outstanding experience, this is the most efficient way to ensure innovative, high-performance solutions for the efficient processing of web-fed materials.

Based on the worldwide success of Schober’s rotary die cutting & stacking machine RSM for in-mould labels, the team of Schober has decided to show its high-speed Twin Spider stacking technology for extremely long and nested products live at Labelexpo Europe in September.

Precise die-cutting and stacking

The machine boasts many special features which allow the precise die-cutting and stacking of thin and flexible films, paper and light cardboard. After the cutting with flexible dies, the products are transported safely to the non-stop stacking zone – ready for banding – an ideal example for automation.

Those who are interested in the latest developments in flexible dies are more than welcome to find out about the latest developments in the field of cutting and creasing plates for cardboard and materials with barrier properties. In addition to the robust design and the excellent adhesive force of the magnets, Schober modules have several sophisticated quick settings to

minimise set-up time.

Exchangeable segments

For high production runs in the tobacco industry, Schober offers either solid or segmented tools, with exchangeable segments. Depending on the wear resistance and lifetime, a wide range of materials is available. From tool steel (SuCR) to powder metallurgical steel (LL) and tungsten carbide (TC). For three-dimensional products, such as blister for toothbrushes, cavitated tool designs are available. For parts, which are too small for die-cutting, Schober offers its rotary punching expertise.

The exhibition team will be looking forward to informing visitors about RSR’s latest developments for the roll processing of

technical films, which can also be used for laminating and further processing of multi-layer products. The RSR has the capability to punch extremely small holes – round, rectangular or shaped – and evacuate the waste particles in a clean and safe manner.

The rotary punching technology is suitable for converting speeds up to 800m/min at a working width of up to 1,800mm – especially for large production runs in the liquid carton industry.

Punching module for different types of tickets

Concerning the converting of special paper, Schobertechnologies will exhibit a high-precision punching module for

parking, event and airline tickets. The heavy-duty design can also be usednfor the punching of corners in tea tags and tea bags. In these applications, an integrated slitting system raises the register accuracy and process stability in the production of narrow single lanes.

For visitors who are still unsure which cutting technology is best for their product, Schober will be highlighting a selection of different technologies. Whether crush cut, shear cut or blade cut – everything will be clearly presented in one display. Schober offers high-tech cutting, punching, creasing, stacking, folding and winding technology in the form of machines, modules or tools to be integrated inline in customers’ converting lines or offline as individual converting machines.

Schobertechnologies will exhibit at Labelexpo Europe in Barcelona: Hall 4, Booth D41.