Zecher GmbH, a leading manufacturer of anilox rollers and sleeves for the printing industry, presents Zecher C.P.T. (Cell Polish Treatment), a groundbreaking advancement in engraving technology. This innovative optimisation method is reported to revolutionise the surface treatment of ceramic anilox rollers and sleeves and raise print quality to a new level.

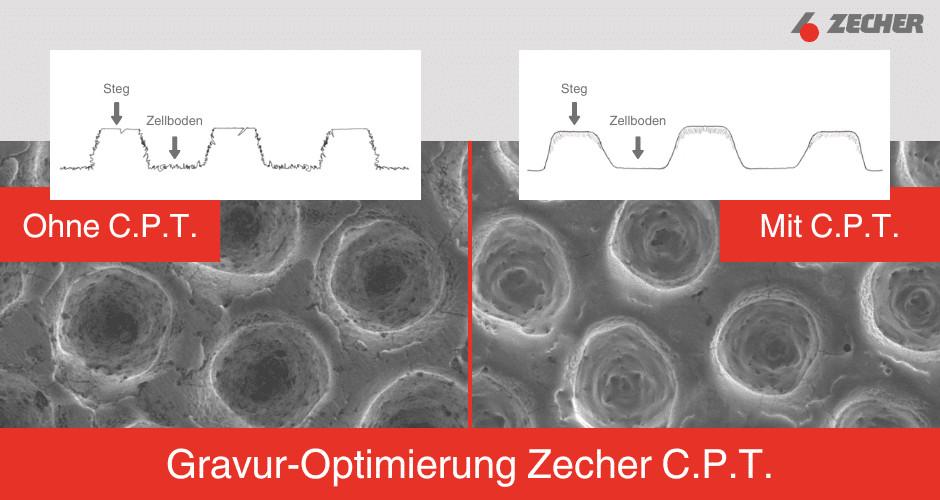

Zecher C.P.T. is a thermal finishing process that is carried out after laser engraving. The process-related sub-microscopic irregularities, such as pores and nano-cracks, which occur during engraving, are thermally eliminated using a new process. This short but precise thermal treatment ensures a “polished” cell structure and strengthens the mechanical stability of the roller surface.

Efficiency through technical precision

The decisive advantage of C.P.T. lies in the optimised characteristics of the cells created by the thermal process. By smoothing the inner walls and strengthening the bridges, the service life of the anilox rollers can be increased while at the same time their performance can be improved. The optimised cells offer a higher mechanical load capacity, which is particularly invaluable when printing at high speeds and with intensive use.

Printing validation and initial customer feedback confirm the outstanding results of the new technology. Compared to conventional anilox rollers, the gravure optimisation offers the following advantages:

- Better emptying behaviour: The optimised cells ensure a more uniform and effective emptying of the cells, which leads to results that are more consistent, especially at high speeds.

- Easier cleaning: Thanks to the smooth cell surfaces, the rollers can be cleaned more easily and thoroughly, reducing downtime and lowering maintenance costs.

- Consistent ink transfer: Even at varying print speeds, the ink application remains consistent, which significantly improves print quality.

- Fewer imperfections: The precise structure of the cells makes the printing process less prone to blemishes, enabling consistently high quality with every print run.

Wide range of applications

Zecher C.P.T. is suitable for all ceramic anilox rollers and sleeves, regardless of their specification. The technology is integrated directly into the production process and complements Zecher GmbH’s existing portfolio without requiring any additional adjustments from printers.

“The constructive development work at the interface between anilox roller production and application technology has enabled us to further optimise the Zecher anilox roller with C.P.T. technology in line with customer requirements,” says Sven Krause, Head of Product Development at Zecher GmbH. “We are convinced that this technology will set new standards in the printing industry and look forward to continuing to convince our customers of the quality of Zecher products through the advantages of C.P.T.”