As part of the innovation network “Hidronik: Hybrid systems with printed electronics”, which is coordinated by ENERGIEregion Nürnberg e.V., Plasma Innovations GmbH is working on the “ALUSolder” project together with the companies Powerlyze GmbH and PCB-Systems GmbH as well as TH Nuremberg (Nuremberg’s Institute of Technology). The aim is to develop resource-saving electronics based on a newly developed aluminium PCB.

The project work is funded by the Central Innovation Programme for SMEs (ZIM) and IraSME – International research activities by small- and medium-sized enterprises.

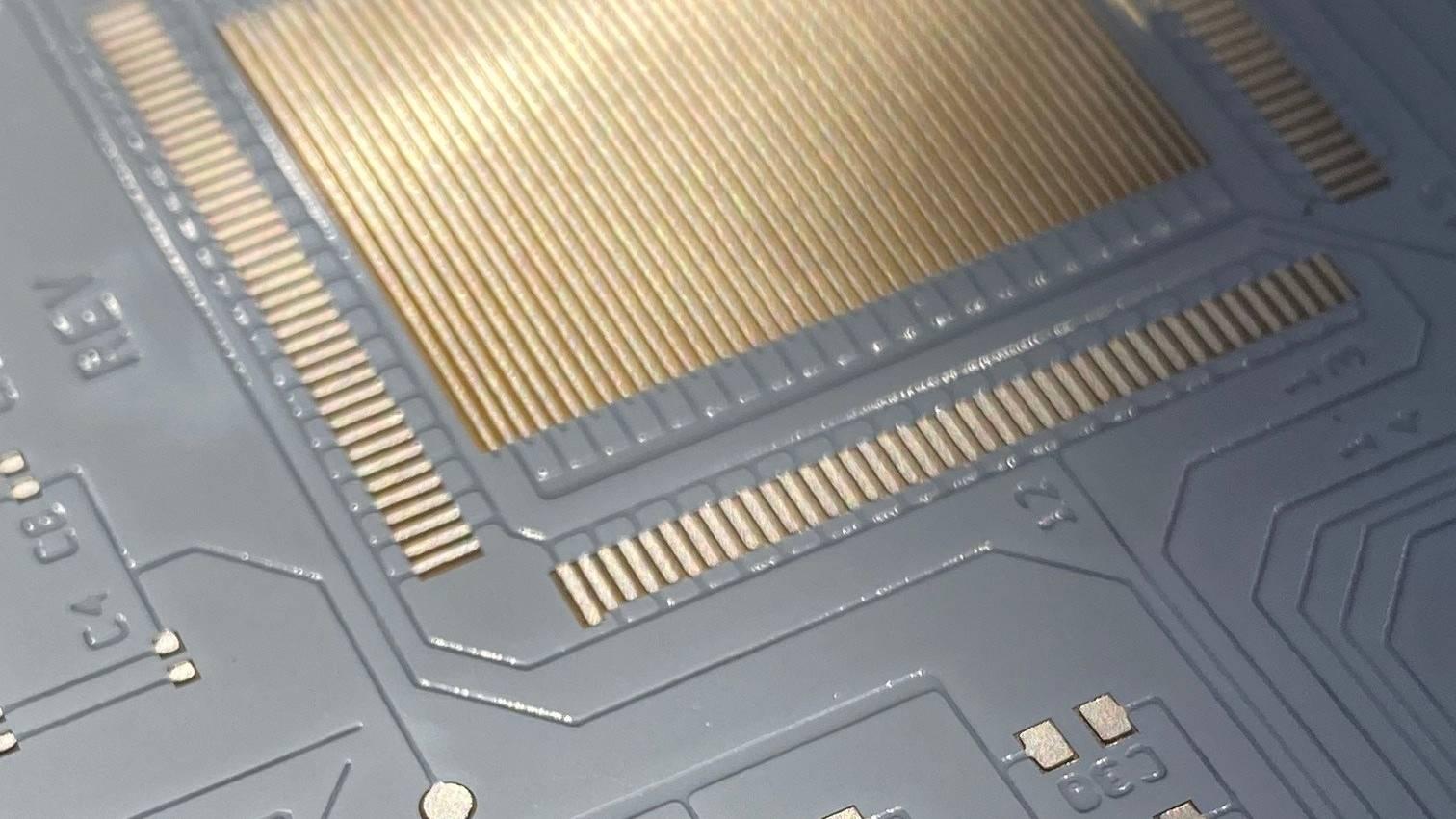

The use of aluminium in the printed circuit board instead of copper makes it possible to switch to cheaper and more readily available materials. This reduces the CO2 footprint during production and conserves valuable raw material resources. It also leads to weight savings. In the case of the IMS (Insulated Metal Substrate) board variant, which was also developed, there are further advantages in terms of recycling.

Excellent market prospects

In view of the growing awareness of sustainability and resource conservation among consumers and companies, the demand for corresponding electronics is expected to increase significantly. The resulting weight saving thanks to the new PCB is a further advantage – especially when considering the requirements for mobile applications.

In addition to the use of climate-friendly technology, there are new opportunities for the users in terms of fully automated, flexible production of printed circuit boards at their own site as well as significant savings in logistics and production.

The innovations developed in the “ALUSolder” project position the project partners involved as pioneers in the industry. Their lightweight electronic modules and the use of printed circuit boards made of aluminium make them more cost-effective, sustainable and resource-saving products.

Technical summary

The aim of the project is to develop a surface and soldering technology based on surface mount technology (SMT) for the production of flexible electronics using aluminium as a conductor track material to replace copper circuit boards. The soldering of SMT components on flexible aluminium conductor structures (ALUSolder) based on the combination of surface finishing, solder paste, process control and system technology has not existed on the market to date. In combination, this results in a new process for surface mounting technology on aluminium PCBs for electronics production. Corresponding long-term test procedures and design guidelines for the layout on these new substrates are being developed in parallel in the project.

Partners in the “ALUSolder” project

Plasma Innovations GmbH, founded in Austria in 2012, is a pioneer in the field of digital direct metallisation (DDM). As an innovative research, development and manufacturing company, it offers a wide range of modular systems and consumables for the production of LED lights, PCBs and MID components. Plasma Innovations GmbH is a specialist in surface functionalisation and plasma technologies and develops new coating technology for aluminium surfaces. It also has many years of experience in plant engineering and production automation.

As a test and inspection laboratory for electronic assemblies, Powerlyze GmbH from Nuremberg has a high level of expertise in carrying out standard-compliant reliability tests from all areas of environmental simulation as well as adequately analysing, characterising and evaluating damage through stress tests.

PCB-Systems GmbH from Bad Aibling is an EMS (Electronic Manufacturing Services) service provider that offers PCB design, hardware and software development as well as the subsequent assembly of PCBs, including the completion of an overall device/system.

With more than 13,000 students, Nuremberg Institute of Technology Georg Simon Ohm – or TH Nuremberg for short – is one of the largest universities in Germany. At the Institute for Chemistry, Material and Product Development (OHM-CMP) at the TH, application-related research and development projects are carried out in cooperation with partners from science and industry, including modern assembly and connection technology as well as process technology for printed electronics.

Innovation network “Hidronik: Hybrid systems with printed electronics”

The “Hidronik” innovation network develops hybrid concepts, products and materials that combine the advantages of printed and conventional electronics. The network brings together suitable partner companies and research institutions. Solutions are developed and subsequently commercialised by means of joint research and development projects. The network is managed by ENERGIEregion Nürnberg e.V.

The competence initiative ENERGIEregion Nürnberg e. V., as a central network platform for the future fields of energy and the environment in the Nuremberg metropolitan region, has been acting as a driving force for innovative projects and as a showcase for regional energy expertise since 2001 and promotes the rational use of energy and resources.

Through dialogue platforms, project initiatives and other services, the ENERGY Region promotes the regional transfer of technology and knowledge and strengthens regional networking and cooperation among its 85 members. Stakeholders from business, research, politics, administration, chambers and associations are thus working together on a secure, cost-effective, climate-friendly, accepted and sustainable energy supply for the Nuremberg metropolitan region.

Caption: Innovative aluminium-based printed circuit board