Panacol has developed a new UV adhesive specifically for foil lamination of organic (OPV) and perovskite-based (PSC) photovoltaic systems: Vitralit UH 1411 is a very flexible, hybrid epoxy resin-acrylate adhesive that cures with UV light.

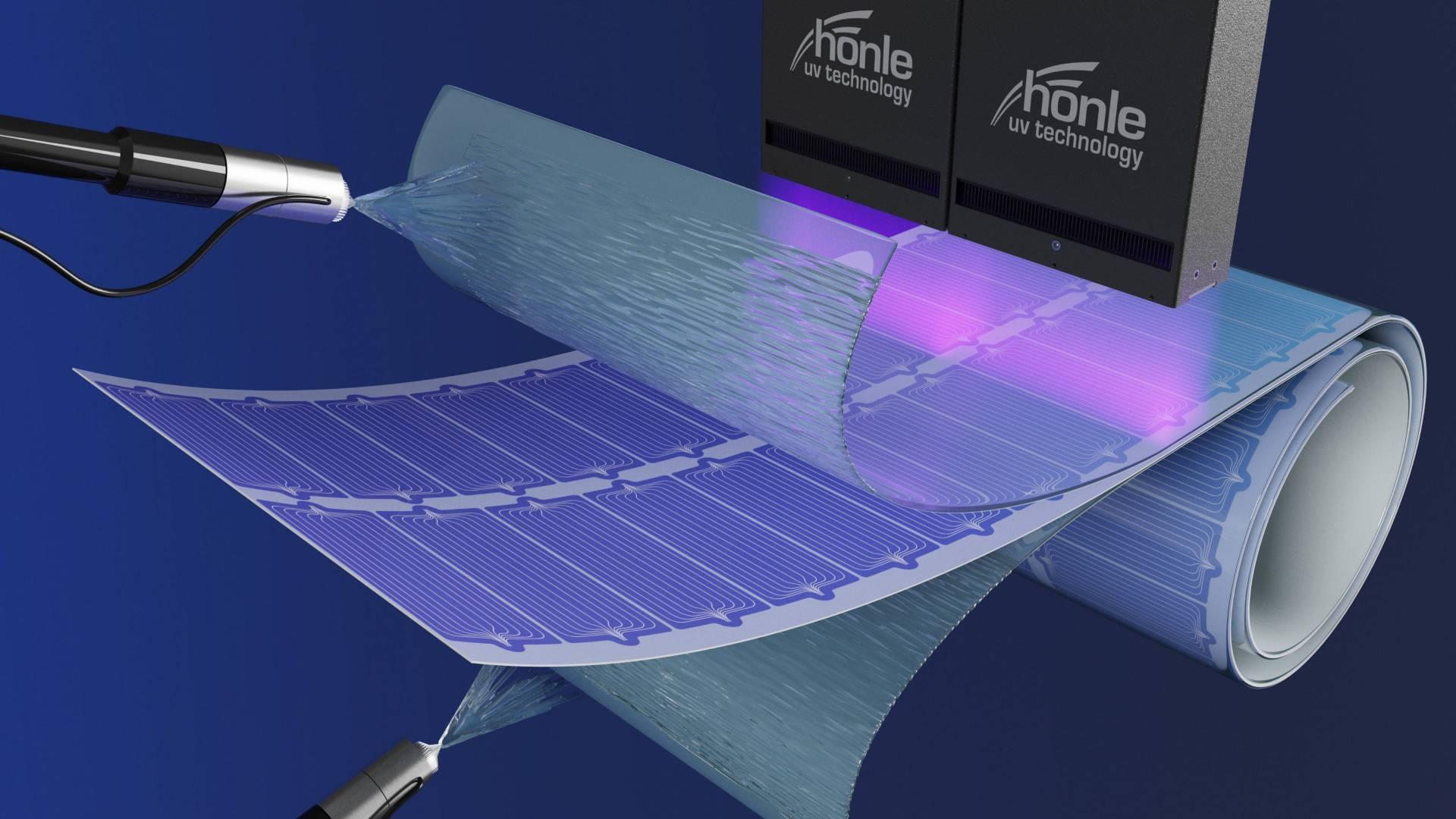

Vitralit UH 1411 is a UV adhesive specially developed for sealing and bonding flexible PV modules. After application, it can be cured by a combination of UV or visible light and heat, which enables precise curing even in potential shadow zones. Dr. Hönle’s LED curing systems, such as the Powerline 820 HP AC IC, are particularly suitable. The modules of the Powerline can be stacked without gaps to completely irradiate the desired width. The intensity is adjustable and can be adapted to the web speed in the range of 10-100%, ensuring consistent curing results. The LED Powerline 820 AC IC HP is supplied and controlled either via the optionally available LED powerdrive IC or via an external power supply unit and customer-side control of the interface.

Resistant to environmental and media influences

Once cured, the hybrid adhesive Vitralit UH 1411 is very resistant to environmental and media influences, as well as being soft and flexible, thanks to its composition of epoxy resin and acrylate components. The new adhesive thus offers an optimised solution for the integration of flexible solar cells in modern indoor concepts.

A key advantage of Vitralit®UH 1411 is its high adhesion to all standard barrier foils and films used in the manufacture of flexible photovoltaic modules. The adhesive strength can be maintained even after high exposure to temperature and humidity. The adhesive is also transparent and non-yellowing, which ensures optimum light absorption and a long service life for the PV modules.

Completely new applications

Organic and perovskite-based photovoltaic systems enable completely new applications both indoors and outdoors. The capture of artificial light indoors can be used to power wireless electronics. The flexibility of the new modules also makes it possible to attach them to geometrically challenging surfaces. The further development of adhesive technologies has made a decisive contribution to these advances. Panacol accompanies these developments by providing innovative high-tech adhesives that can be individually adapted to the relevant customer application.

Panacol will exhibit at LOPEC from 25-27 February, Stand B0 614.