Converters that print, coat and laminate and who have navigated their way through the various challenges of the last few years, are well grounded in process and commercial reality, they accept that they may need to look beyond the every day. Times change and change is constant. Many astute printers and converters are therefore looking to stake a claim and make an impression in product sectors and markets that are continuingly developing and evolving.

Printed electronics (PE) opens up new possibilities and in some instances can be regarded as an alternative to silicon-based electronic manufacturing procedures. Print processes such as flexo, gravure, digital, screen and various converting process such as coating can be used for applications where silicon-based fabrication is not feasible, for reasons, such as cost, flexibility, customisability and speed.

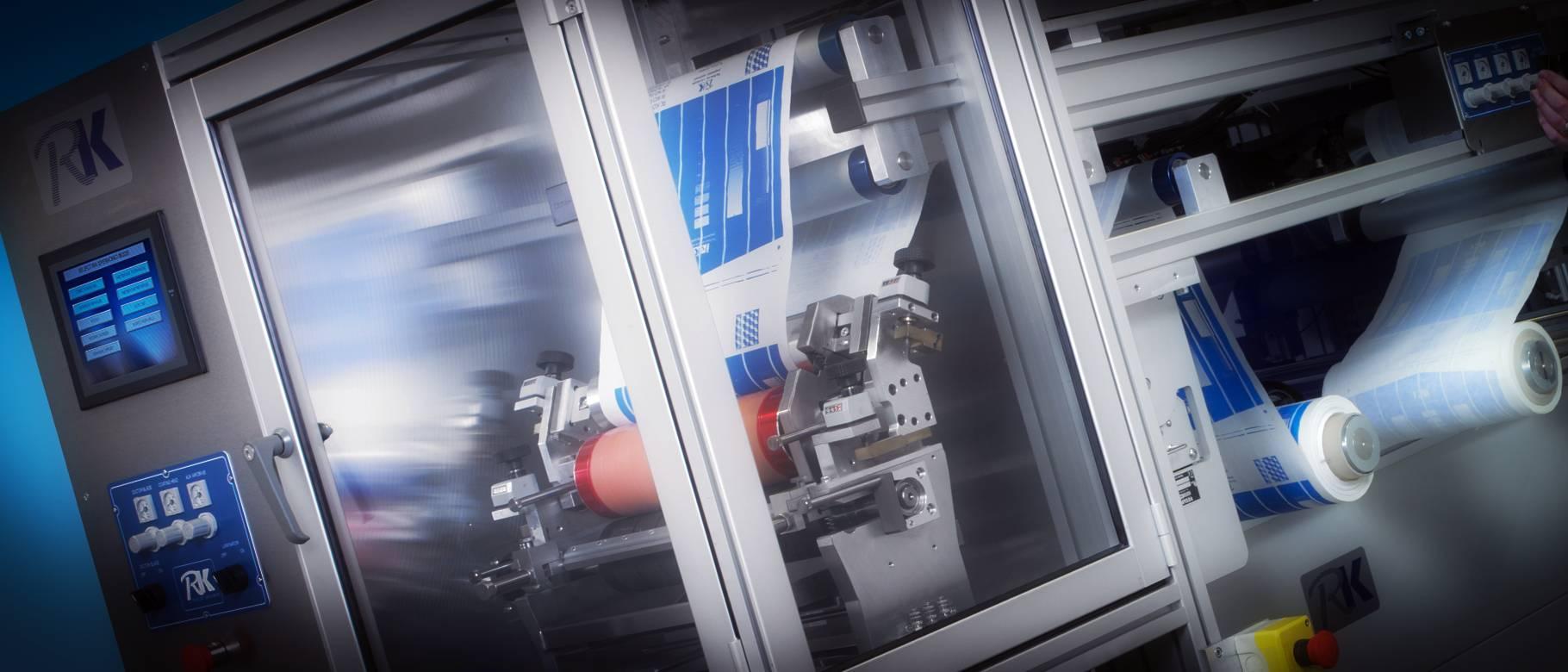

Flexo may be a good fit in that faster press speeds, new processing concepts; such as flexo-hybrid presses and advancement in consumables and in support technologies make the process competitive. RK Print Coat Instruments Ltd have supplied customers with coating and printing systems for flexible printable electronic applications centred around the production of batteries, antennas, OLEDs, Photo-voltaic’ printed circuits and pharmaceutical wearable’s, etc.

VCML for IIT Kanpur

A VCML has been designed, developed and installed at IIT Kanpur, a prestigious technical university in India. This VCML is custom configured and is being used for the development of printable electronics (PE) using print processes such as gravure, flexo and screen printing in various combinations, with print registration options and coating and laminating. A VCML has also been supplied to another customer for coating onto 8-micron copper foil with slurry for batteries.

The VCML with a working web width of up to 300mm and with the ability to undertake short runs make the design and specification of the system suitable for R&D purposes, trialling, monitoring and determining commercial and product viability. The VCML can print, coat, laminate on all types of flexible substrates. It can be configured for clean room conditions, which are often a requirement for many electronic components. Drying options include hot air, IR and UV curing. It can be ATEX zone protected and accepts major print and coat head technologies including, gravure, flexo, slot die, extrusion coat, etc.

Slot die coating is one option. It can be ideal where thin or optical clear coatings need to be laid. Slot die can be used to apply fluids or polymers such as adhesive, inks and electrolytes onto continuous thin substrates and which may be used for displays, medical patches and in battery production. Unlike many coating technologies that are open to the air, slot die provides for a closed delivery path and a more sterile coating environment with minimal evaporation.

Printing on many different types of substrates

Gravure printing and coating may also be considered. Gravure coating differs from gravure printing in that gravure coating provides uniform coverage of the substrate whereas gravure printing prints defined patterns with good edge definition and resolution. Some electronic products however require uniform coverage and good edge definition.

One of the advantages of PE is that it can be used to print on many different types of substrates. It is also possible to print thin and on flexible and lightweight mediums such as very thin polymeric films and on biodegradable and on paper, textiles, glass, metal, wood and synthetics. Paper is a popular base for printed electronics due to its flexibility and the ease of which the inks adhere to the surface. Sensors that are printed on flexible substrates are a particular area of growth. Applications include biosensors for medical monitoring and diagnostic purposes touch sensors and transducers. Communicative device development is on going and that includes antennas for hand held devices, automotive and aircraft.

Written by Tom Kerchiss, Chairman of RK Print Coat Instruments Ltd