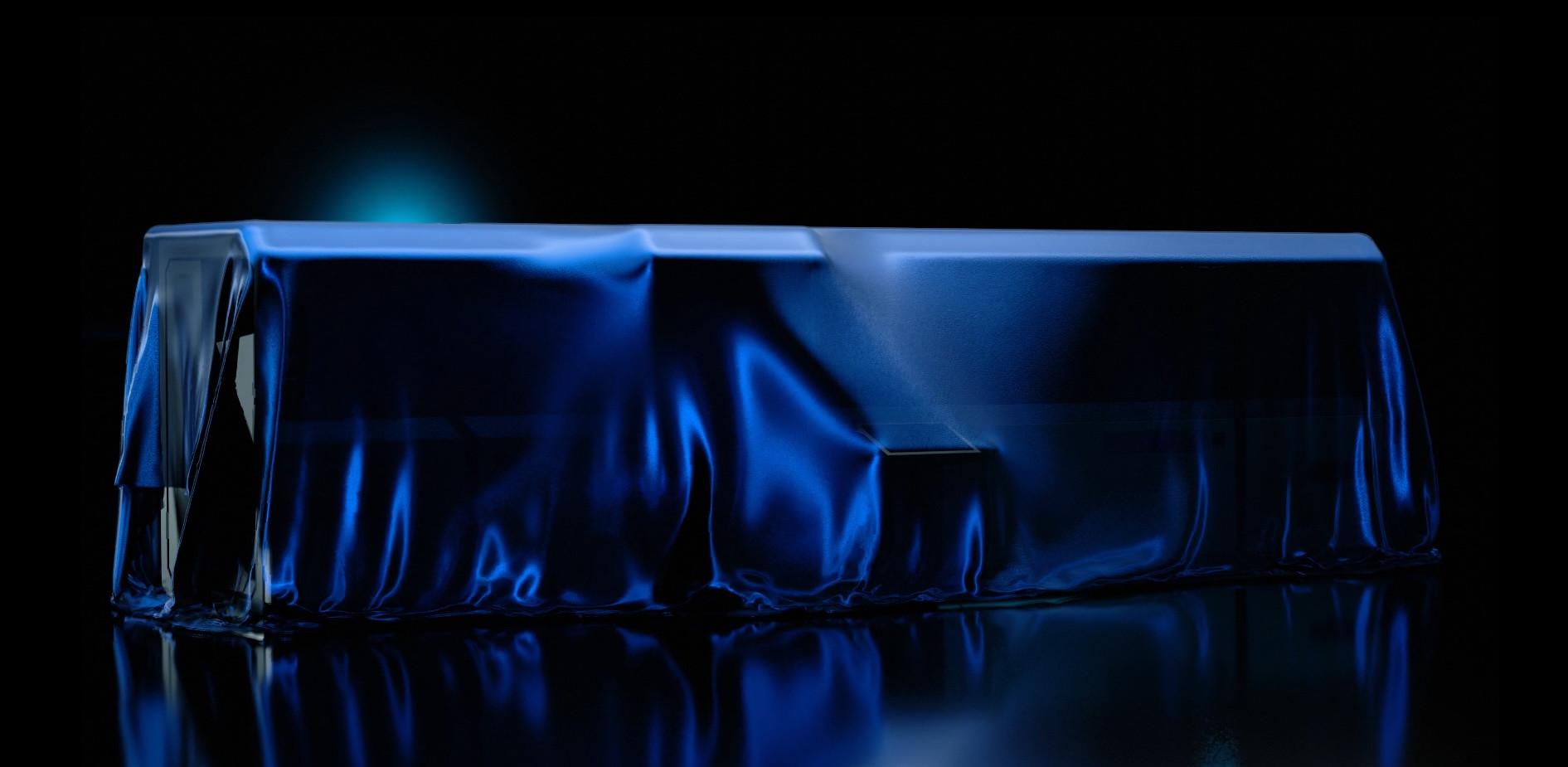

SPGPrints has announced the upcoming launch of an innovative, high-quality, entry-level rotary screen (RSI) printing line. Designed to empower organisations, Basalt offers a cost-effective solution for testing and qualifying printed electronics applications. Its modular design ensures flexibility and adaptability, making it the perfect choice for those looking to explore new possibilities before scaling up.

The new Basalt printing line with RSI technology is the latest innovation from SPGPrints. It is the steppingstone from lab-scale and flatbed screen printed electronics towards full scale and high-volume production.

Printing conductive and dielectric inks on flexible substrates

Printing heating elements, (bio-) sensors, solar panels or any other application that involves printing conductive and dielectric inks on flexible substrates, can be done efficiently and cost effectively with rotary screen printing. The ability to print continuous design is also a great benefit that rotary screen printing offers. According to SPGPrints, Basalt is the perfect entry into high-volume screen printing.

The Basalt printing line comes in various widths and is a ready to go machine to start printing. It contains unwinding, printing, drying and rewinding modules. Basalt will be offically launched at the LOPEC 2025 Exhibition in Munich.