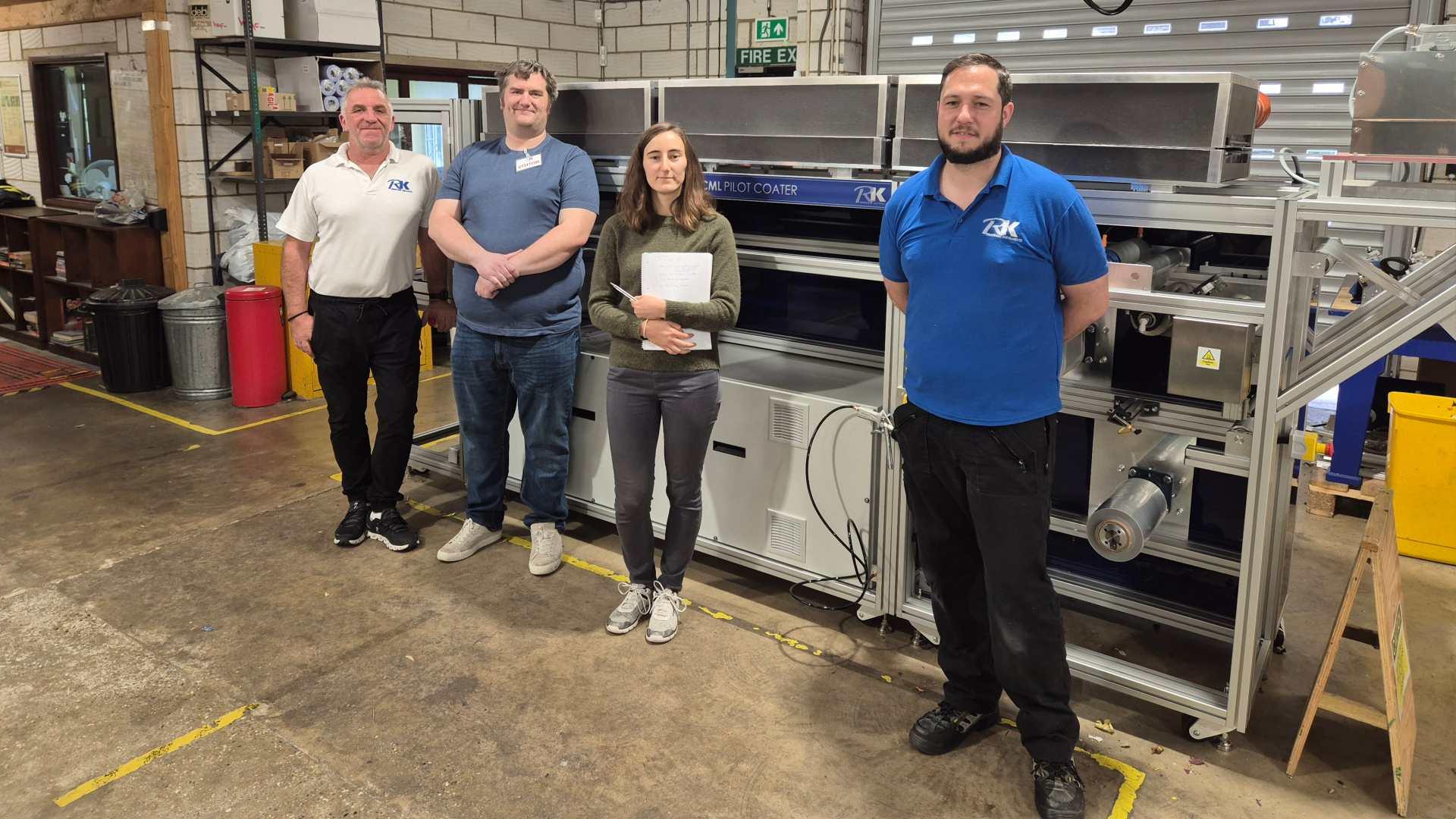

RISE PFI, part of RISE: Research Institute of Sweden have purchased a VCML pilot coater from RK Print Coat Instruments Ltd. The VCML supplied to RISE PFI at Trondheim, Norway is provided with reverse gravure and knife-over roll coating. This coating system is also provided with three hot air impingement dryers and supports Infrared (IR) curing and has an edge guide and heated laminator.

RISE PFI’s applications are quite complex due to the nature of the substrate and the use of Nano cellulose. The VCML will be used for the research and development, trialling and implementation of efficient and cost-effective fibre conversion technologies including fibre-based composites, Nano fibre production and functionalised packaging.

Meeting the specific requirements of development

The VCML pilot coater offers short run capability and may be configured to meet the specific requirements of those companies engaged in the development and bringing to market more environmentally acceptable products.

Selectable coating/print and other processing options include: slot-die, knife-over-roll, direct/reverse and offset gravure; meter bar, rotary screen, reverse roll and wet and dry lamination. Drying options include hot air, infrared and UV curing. The VCML can be supplied for operating in clean room conditions and zones may be ATEX protected.

Printing, coating, laminating

The VCML is a fully functional roll-to-roll processing system optimised to print, coat and laminate on all types of flexible substrates. Various coatings including inks, varnishes, adhesives, paint, as well as materials being developed that make use of water-based technologies can be applied.